The technology centre and Grupo Erlo are currently developing a connected and automated machine to manage thread quality and improve process efficiency. This collaborative effort is critical to deliver solutions that SMEs can implement in the field of Industry 4.0.

In this industry, it is nowadays possible to monitor equipment by using technologies such as Artificial Intelligence and Machine Learning to obtain real-time information on status and any errors that may have occurred at a given time during production. What this implies for companies is greater reliability and availability of equipment as well as the possibility of measuring the degree of component wear to anticipate decisions.

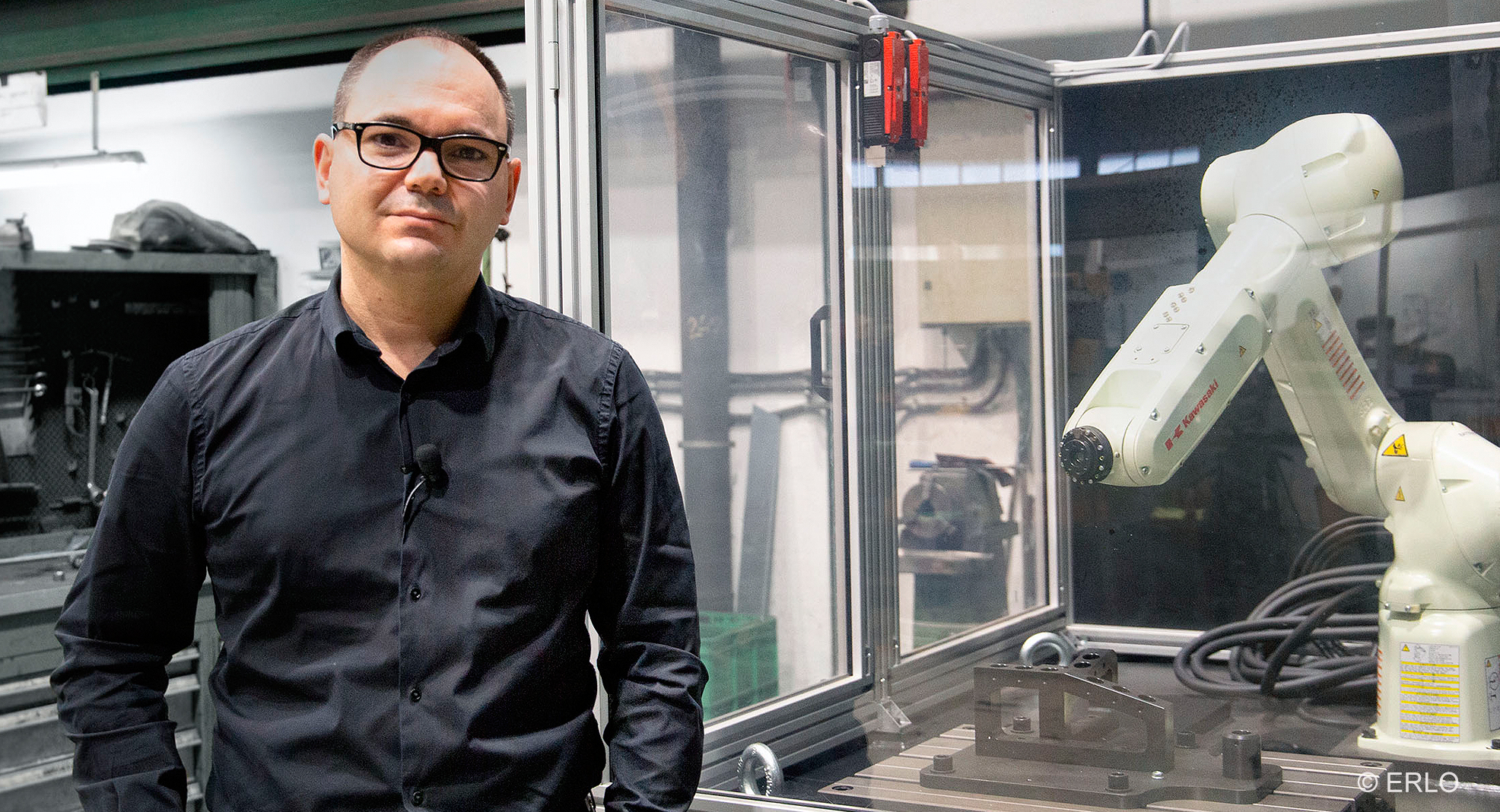

It is in this context that Grupo Erlo, specialised in cutting and shaping solutions, has noted that obtaining information on thread quality is extremely important, for instance, in the case of customers from the automotive and aeronautical sectors.

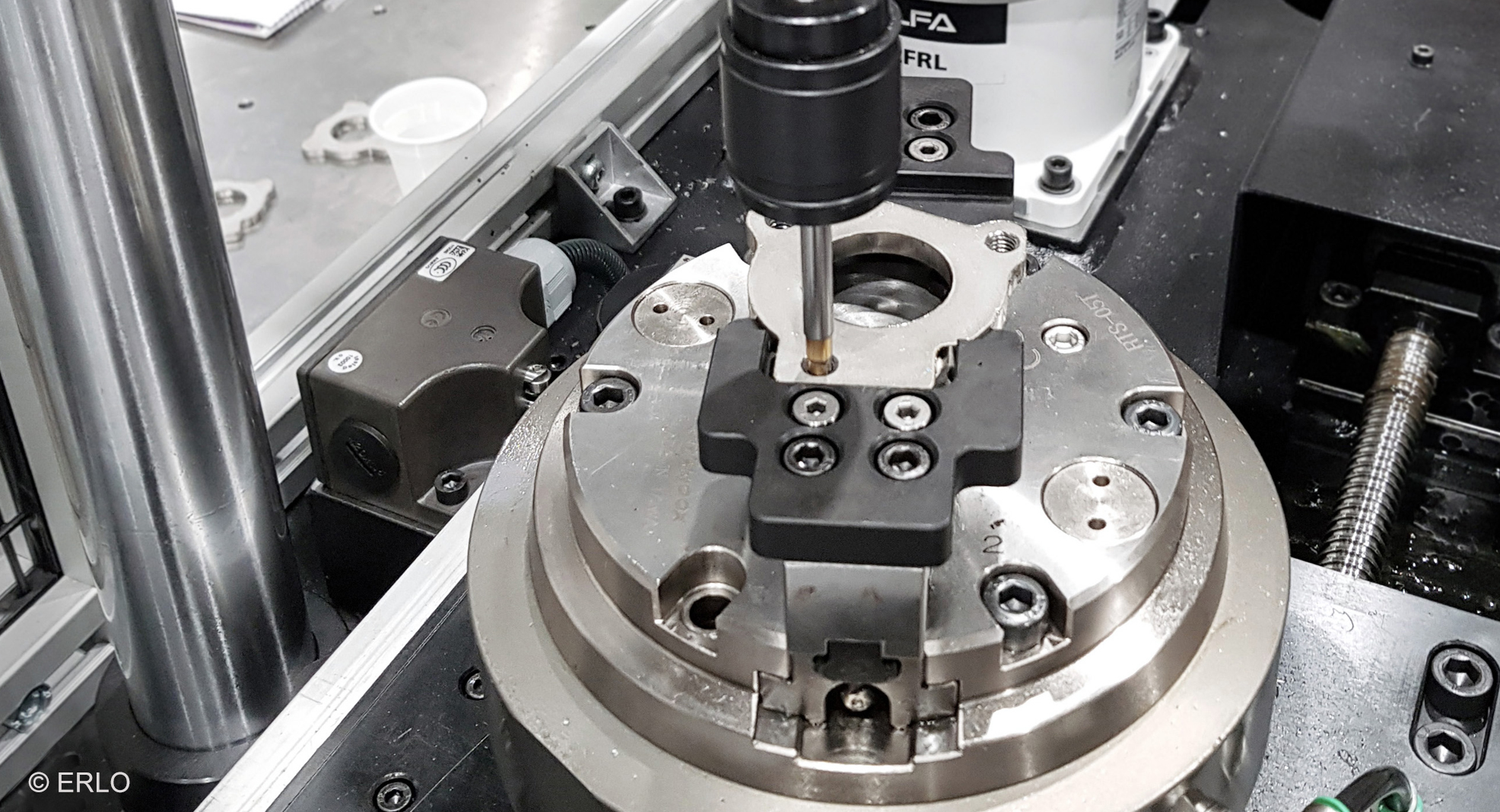

Consequently, Tekniker, a member of the Basque Research and Technology Alliance (BRTA), is currently collaborating with Grupo Erlo to develop a connected machine featuring technologies such as Edge Computing to gather information on threads to manage product quality. Specifically, it is a thread tester that offers cloud-accessible data for real-time monitoring. In this manner, a machine will be able to send critical information to customers to improve process efficiency. Among other benefits, this technology provides early detection of thread failures, lower production chain costs and greater efficiency.

Thanks to this collaborative action, Grupo Erlo and Tekniker have been able to set up a long-term strategic partnership that is essential to enhance the competitiveness of the industrial fabric and delivers Industry 4.0 solutions that SMEs will be able to implement gradually.

In this particular case, the technology centre has supplied its know-how in terms of Industry 4.0 and connected machines to offer solutions and improvements for equipment via the acquisition, processing and analytical capabilities provided by sensors to detect potential operational anomalies, perform condition diagnostics and predict potential failures.

The technological proposal is based on adapting the Big Data SAM Smart Asset Management platform, one of Tekniker’s technological assets, to enable the storage and subsequent analysis of any data received. But in addition to the platform itself, a connection is required to collect and store the information recorded by a datalogger to make it available to Grupo Erlo, so that in the future all machines can be included in other production monitoring systems.

The early detection of thread failures has not only allowed Grupo Erlo but also other companies to achieve higher degrees of process productivity and efficiency. Additionally, and thanks to this technological proposal, production chains will gain in efficiency as verification stages will be shortened.

If an incident occurs, this technology will also provide companies with information on process traceability as well as relevant safety data. Likewise, and whenever a part fails, it will be possible to discover what actually caused the problem.