THE EXPERT'S VIEW

Due to the global economic situation in recent years, many industrial sectors have, in one way or another, been through a kind of reconversion of their business models.

Even though the processing of materials continues to be an active part in the industrial chain, a high percentage of funds as well as companies have shifted their attention to the maintenance of assets in service, a field that has seen ongoing growth in recent years.

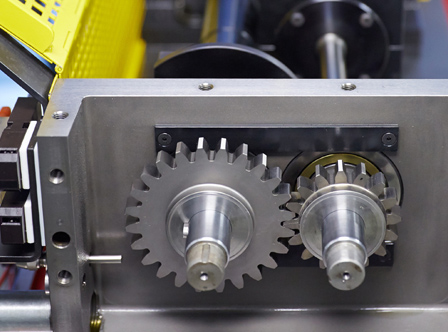

By definition, maintenance is about all the necessary actions that aim to preserve or restore the state of an asset so that it performs the desired function.

From the start of the industrial revolution up to the most advanced state of production today, maintenance has played and will continue to play a highly critical role, because the activity of industrial business depends on it.

Industry has a long list of actions geared towards maintaining the state of its assets; the actions were gradually modified in line with the design of new and more modern components and were coupled with the actual advances in the available tools. Despite this, with the current availability of technology, many maintenance actions are still carried out within the threshold of not knowing and without making any contribution at all to the business activity or with the orientation focussing on maximising results.

Today more than ever these actions require a holistic view covering the asset, its environment and integration with communication technology, analysis and data processing. This last concept comes within the framework of IK4-TEKNIKER’s Smart Asset Management (SAM) line.

Transfer to the industrial sector and IK4-TEKNIKER’s role

For a long time, IK4-TEKNIKER has been an international benchmark in many spheres relating to maintenance tasks, such as the analysis of industrial oils and fluids, product dependability, monitoring and information acquisition, and support in decision-making and management, among other things.

The technological integration of these spheres in accordance with the aims of advanced specialisation and, at the same time, with market goals constitute a significant challenge for any company. This is the new role of IK4-TEKNIKER’s SAM line: to achieve the complete integration between traditional maintenance and the currently available technological tools. To achieve better productivity and efficiency in manufacturing processes based on avoiding the replacement of equipment in accordance with the “4.0 Industry” report.

The scope of this maintenance vision is broad and can be easily adapted to single critical equipment on a plant going right up to the analysis and processing of fleet data.

Success stories:

Processing fleets

Data processing of fleet operation and maintenance with the aim of determining common fault patterns over time; the result is the maximising of maintenance tasks on the basis of the condition of the components.

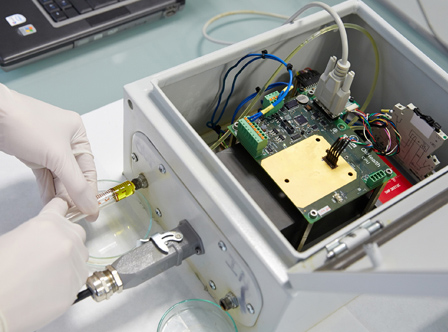

Incorporation of online sensors and oil analysis

It is becoming increasingly common that equipment in remote or highly critical locations should have at least one type of sensor to monitor their state. Current technology has enabled a new, powerful suite of online oil sensors (Atten2) to have a place within this framework, thus making the immediate availability of certain indicators of the state of the oil or the component possible. In this respect, the sensor does not replace the lab, nor the other way round; both in an integrated way maximise the information by making more precise programming and planning margins of tasks associated with maintenance possible.

Analysing operating and maintenance data

A large percentage of equipment in remote or highly critical areas generate a vast amount of information; in many cases, making all this information available poses a problem rather than an advantage when it comes to using it properly. The proper processing of it by using analysis tools adapted to each detection, diagnosis or prediction phase makes it possible to align the data processing with the optimising of the operation and maintenance of the equipment.

SAM tools not only allow the global diagnosis of the equipment to be optimised, by applying methodologies such as machine learning or clustering data geared towards the prognosis of situations prior to breakdown have also been obtained.