PROJECTS

Solutions that deliver quicker, more reliable, flexible and productive manufacturing processes and improve the quality of the end product.

Demands in terms of production resources are becoming increasingly stringent in the field of advanced manufacturing. In sectors such as wind power, aeronautics and the naval business, the current trend is to manufacture larger parts although preserving the accuracy of their predecessors. In the case of the automotive sector, the main focus is to maintain size, although increasing the degree of accuracy of the end product.

In order to address this new scenario properly, IK4-TEKNIKER has initiated the MH2020 project that, on the one hand, intends to increase the accuracy of machine tools throughout their entire work volume and, on the other, wants machine tools to incorporate capabilities so that measuring can take place with dimensional traceability.

There are parameters such as the size of a part and of the machine tool itself, variations in environmental conditions or the measuring technology that must be analysed and receive special attention. To this end, it is necessary to develop rapid and automatic verification procedures, run simulations of measuring procedures or to create hardware and software allowing machine tools to perform measurements.

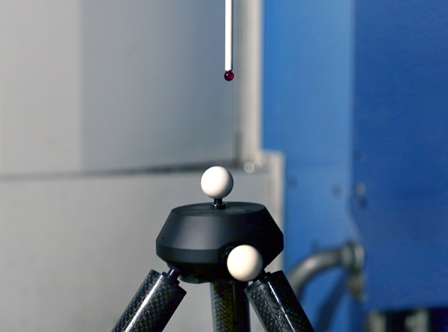

Market trends are leaning more towards the design and production of machines that are more accurate in their entire working volume and are equipped with measuring capabilities to perform traceable operations on the machine. To achieve this goal, geometric and environmental monitoring tools are installed in addition to sensoring probes to ensure data collection on the machine itself.

In this regard, both the knowledge that IK4-TEKNIKER possesses together with it highly recognised degree of specialisation in top range metrology have allowed the centre to become an outstanding stakeholder in terms of the goals achieved.

Other companies are also involved in the project such as Goratu, Soraluce, Fagor Automation, Gometegi, Unimetrik Metrology o Calibration and Ekide together with stakeholders from the Basque Network of Science, Technology and Innovation such as Innovalia Metrology, Aotek, Vicomtech-IK4 or IK4-IDEKO.