Tekniker presents Tekniker Fingerprint, its new periodic condition monitoring test for machines.

The Tekniker technology centre, a member of the Basque Research and Technology Alliance, is strongly committed to offering real solutions allowing companies to advance in terms of Industry 4.0. Consequently, and via its Clickindustrial e-commerce platform, the technology centre has incorporated a new service called, Tekniker Fingerprint, a periodic condition monitoring test used to check critical components and detect abnormal operating situations in an early stage.

It is important to monitor machine condition to implement correct predicative maintenance actions geared towards improving quality in terms of time margins and process costs. This also optimises equipment performance, increases availability and extends operating life.

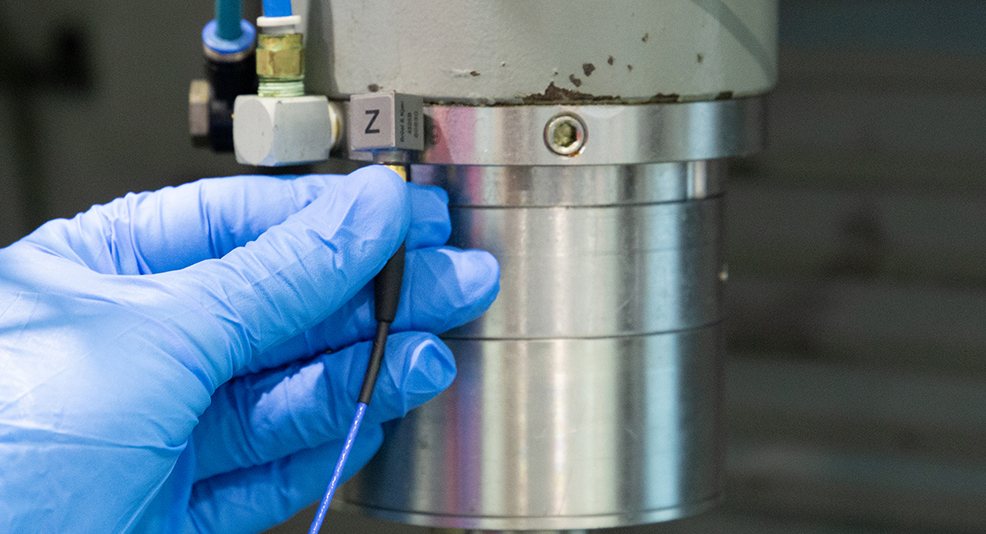

This machine tool condition monitoring and use data management tool features four steps: collection, diagnosis, analysis and optimisation. Firstly, Tekniker Fingerprint compiles and processes the signals delivered by the machine and its components. After compiling the data, the system identifies parameters related to use, operation and condition for each type of machine. This is how it also allows the normal operating range of a machine to be characterised.

Once a condition diagnosis has been established for the machine, the system visualises and monitors the evolution of machine and component indicators. As a result of performing this analysis, machine availability is improved and planning actions for maintenance and spare part management are optimised.

For additional information

Machine Condition Monitoring Test