The technology centre has applied its expertise in the areas of AI algorithmics and physical modelling by developing digital twins that can improve control fault detection and monitoring processes for industrial assets.

Simulation tools such as digital twins are increasingly being applied in Industry 4.0 environments to improve production process efficacy. These virtual models of equipment that allow you better understand and predict the performance features of real-life or physical equipment. They are used throughout the equipment’s entire life cycle to simulate, predict and optimise equipment operation before investing in prototypes and physical equipment.

The Tekniker technology centre is currently looking into these technologies within the framework of the VIRTUAL project in which AI has played a specific role in terms of generating models based on the knowledge acquired by using real data.

Thanks to AI techniques, Tekniker has been able to hybridise the typologies of physical models pursuant to data to maximise their potential. In this manner, for instance, it is possible to adjust physical or complementary models to simulate certain situations or physical effects that are hard to explain; the models can also be used to recreate data that is difficult to gather and register in the industry (such as machine faults), to enable the the development of AI models that could never materialise without the aforementioned data.

More specifically, Tekniker has applied all of its knowhow in the areas of AI algorithmics and physical modelling to generate digital twins.

These twins are especially interesting in cases when only few asset fault data are available or whenever the availability of equipment to be commissioned is low and the aim is to develop monitoring actions in advance.

The combination of synthetic data (i.e., data generated by physical models) with experimental data by means of AI algorithmics delivers machine fault diagnostic and detection systems that are more robust and reliable.

Hybridisation techniques of this kind are of great interest in industrial environments where assets are very costly and the aim is to prevent malfunctions. Generally speaking, and in order to prevent malfunctions, assets are subjected to continuous monitoring. Continuous monitoring also hampers the gathering of fault data required to obtain enhanced diagnostic and prognostic systems for these assets. Consequently, and thanks to the data hybridisation procedure proposed in VIRTUAL for electromechanical actuators it is now not only possible to address this problematic issue but also improve monitoring systems significantly.

The technology centre, on the other hand, has applied what is called a virtual commissioning methodology in which virtual models are used to check equipment control software before it becomes available (connection and virtual commissioning of the equipment) in such a manner that tests are run in early project stages to detect errors in advance and reach the commissioning stage with software that is more refined.

When applied to equipment software programming, this methodology offers a large number of improvements that can summarised as follows: the amount of time required for commissioning is reduced to a minimum, risks are significantly mitigated, it become possible to run automatic tests and avoid repetitive errors, software quality is improved and software maintainability is enhanced.

Consequently, the VIRTUAL initiative has developed digital twins that allow you to test, correct and validate equipment software before having physical equipment at your disposal to fine-tune operations on real-life equipment.

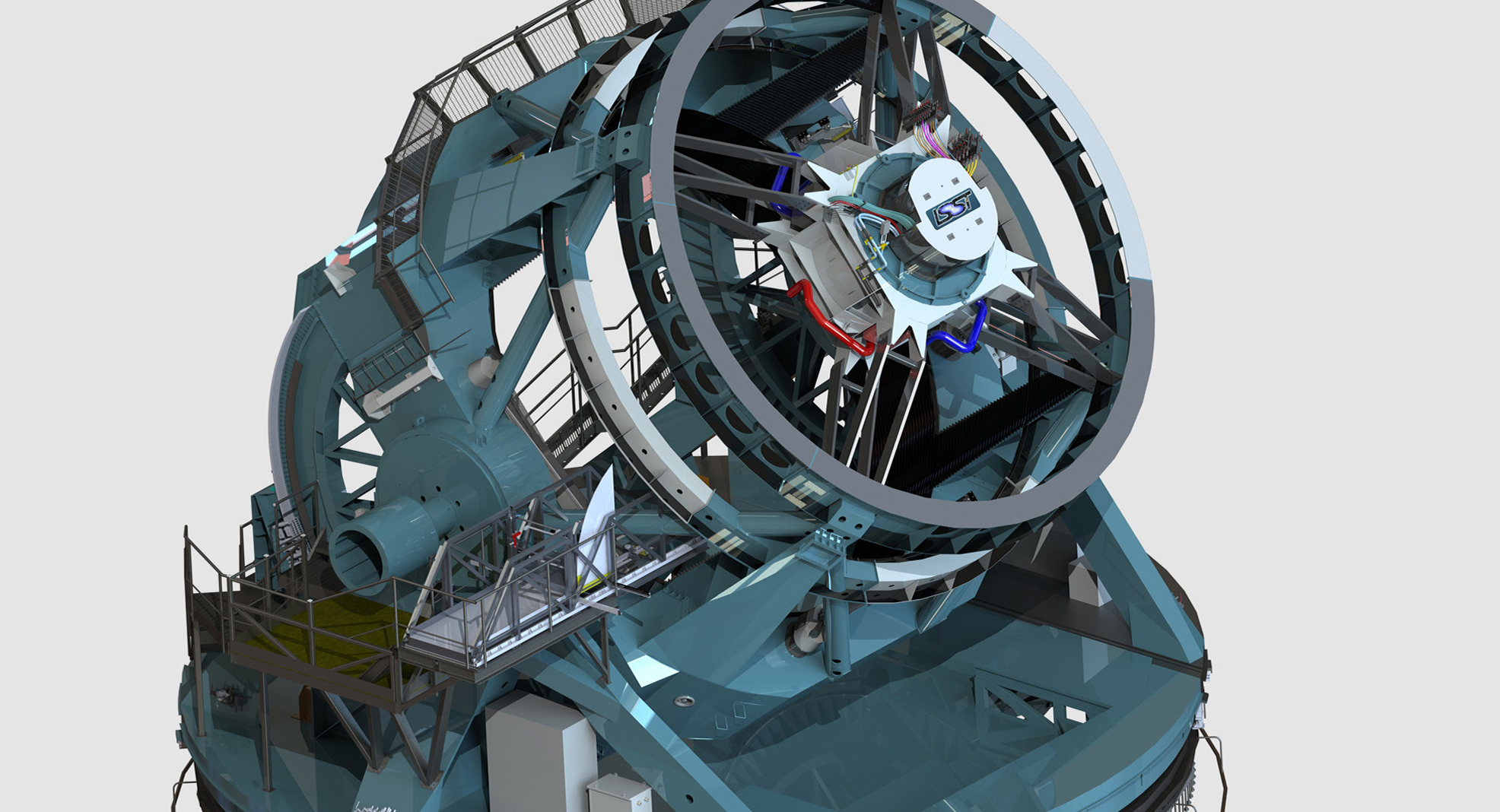

Likewise, and within the framework of this project, Tekniker has contributed, on the one hand, its knowledge in areas such as mechanics, electronics and monitoring and, on the other, in-house expertise in terms of AI algorithmics to develop models and optimise the size and design of gearboxes, speed up the design of brake-clutch control systems and components for the Large Synoptic Survey Telescope (LSST), currently under construction. Finally, the organisation has designed diagnostic systems for electromechanical actuators.

Several universities and technology centres of the Basque Country are involved in the VIRTUAL project funded by the ELKARTEK programme.