THE EXPERT'S VIEW

Advanced robotics

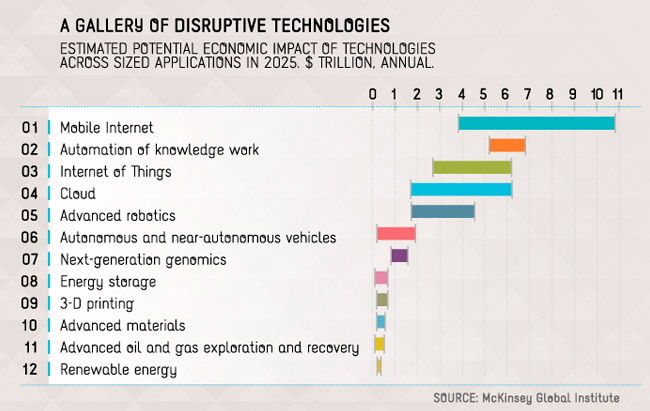

Right now Advanced Robotics falls within the scope of what are known as Disruptive Technologies, the ones whose advance is set to transform our future lifestyle, business and economy. In this respect, Advanced Robotics is seen as an opportunity for addressing various global needs like the evolution of the world of manufacturing towards flexible manufacturing, or the ageing of the population, and the resulting increased demand for care.

Robotics research is geared towards developing robots that are increasingly more capable and sophisticated, equipped with improved sensors, skill and intelligence, to automate complex tasks or increase human capacities. The challenges facing the development of this new generation of robots are totally different from those of the previous generation, industrial robots.

Ever since robots were introduced into manufacturing systems in the 1960s it has been difficult to imagine a factory without them. Their capabilities in terms of power, speed and precision offer great advantages from the point of view of product quality, working conditions and safety, efficiency and productivity while automating operations and minimizing errors. Today, Industrial Robotics is a mature technology, indeed, it is an essential component of manufacturing worldwide. Robots are used to carry out tasks that are repetitive, hazardous, and involve little added value. Among the typical applications of Industrial Robotics are welding, the handling of parts, painting and surface treatment. The manufacturing industry remains the most important market for robots and, within this sector, car manufacture is a key area of application.

Developers of industrial robotics applications guarantee structured, known environments in which the robots carry out repetitive tasks, and safety is ensured by means of physical separation barriers. However, right now, demand, even in the industrial ambit, is being geared towards a greater level of flexibility, in non-structured and even unknown environments with direct person-robot interaction and, what is equally important, at a low cost.

On the other hand, robots are increasingly making their entry into the public domain and into the home, a clear example being robot vacuum cleaners or robot lawnmowers. Robotics applications are expanding and the concept of Service Robot is emerging; it is usually defined as that which develops robotic systems to help people in their everyday lives, at work, in healthcare and helping people with specific support needs. Service Robotics is normally divided into two main groups: professional and personal. Unlike industrial robots, service robots perform tasks in spaces occupied by people and in some cases in collaboration with them. This renders aspects relating to safety, as well as ethical, legal and social questions even more critical.

IK4-TEKNIKER’s expertise in Robotics

To address the challenges being posed by the new generation of robots and within the new philosophy of IK4-TEKNIKER’s expertise, one of the future commitments in technologies is Advanced Robotics. Even though IK4-TEKNIKER’s research activity is structured around Technological Research Units, its expertise in Advanced Robotics cuts across various Technological Units.

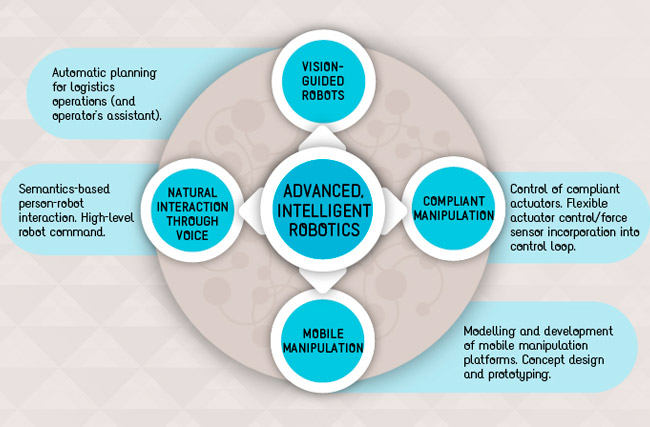

In the specialisation we establish the main cornerstones and future vision of Robotics at IK4-TEKNIKER: vision-guided intelligent robotics, force-based flexible control, natural person-robot interaction, and mobile manipulation. The aim is to achieve the capabilities for developing robots that offer better features like new compact, adaptable designs, easy programming and usability, safe person-robot collaboration, etc.

At IK4-TEKNIKER we have been participating in projects in Spain and on a European level in the field of Advanced and Applied Robotics. The portfolio of R&D projects comprises industrial robotics and service projects. The quest for innovation in robotics is implemented in various technological developments that enable us to do the following:

- To expand the applications in industrial environments and to offer new services in the professional as well as personal environment. The introduction of robots in other ambits in which right now they have had little penetration like food, textiles, etc., or in small enterprises by adapting to their need for greater flexibility and increased returns on investment.

- In the industrial ambit, to address practical requirements in production by seeking solutions that will make flexible automation possible by offering high performance in safety.

- In the service ambit, to develop new robotic applications like the inspection of large pieces of equipment or industrial plants where maintenance costs are high. In this field there are challenges when it comes to integrating robots into environments that are not specially adapted to their characteristics; such environments are a priori unknown, continually changing, and with considerable interaction with people.

- The convergence between mechatronics and cognitive science, artificial intelligence and information technology to create smarter robots with advanced capabilities and features.

- Close collaboration between people and robots without the physical barriers that currently separate them. Person-robot co-operation that enables the capabilities of people and robots to be combined in order to automate processes that previously were not economically viable. Over the coming years people will probably start to interact directly with mobile robots in industrial and in more familiar environments. At IK4-TEKNIKER we are working to develop technologies for autonomous and safe navigation in dynamic environments. Likewise, mobile robots will be fitted with manipulators, the control of which has to ensure safe, hazard-free interaction with people and allow these robots to carry out more complex mobile manipulation operations.