PROJECTS

The aim of this study was to reproduce the wear mechanisms for the sealing systems of pneumatic hammers to know how to respond to each type of seal and material under actual working conditions.

Seals are critical elements of a variety of industrial products. The aim of this study was to reproduce the wear mechanisms for the sealing systems of pneumatic hammers to know how to respond to each type of seal and material under actual working conditions.

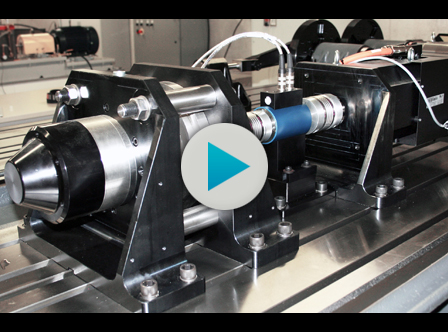

To address this study, IK4-TEKNIKER designed a specific test chamber to test piston seals at a linear velocity of 6 m/s and pressurised with compressed air. During the wear testing, the pressure in the chamber and the temperature in the sleeve were monitored with the aim of measuring possible leaks and frictional heating, respectively, during the test.

Fatigue, extrusion and thermal degradation were the main failure mechanisms identified.

Fields of application

Energy, Capital goods, Machine Tools, Transport.