NEWS

The prototype will be on show at the IK4-TEKNIKER stand at the Machine-Tool Biennial taking place at the Bilbao Exhibition Centre (BEC) between May 28 and 2 June. The equipment is geared towards industrial applications, like the automotive industry, biomedicine or microfluidics.

The welding of plastic components by means of fibre-optic guided laser is a technique recently introduced into industry and which offers advantages over other conventional methods: minimization of thermal distortions in the welding area, greater efficiency and greater flexibility.

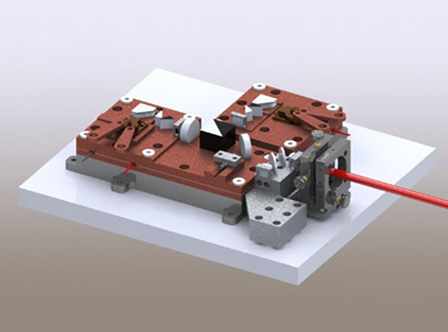

Bearing in mind the potential of this sector, with industrial applications for the automotive industry, biomedicine or microfluidics, IK4-TEKNIKER has developed the WELAS project: a laser designed for welding plastics that enables a broad range of components to be assembled. This Basque R+D centre has also begun a process to incorporate this device into a welding machine, and is currently working on the prototype. The project has been developed with 100% in-house technology on the mechatronics side and in the development of the laser.

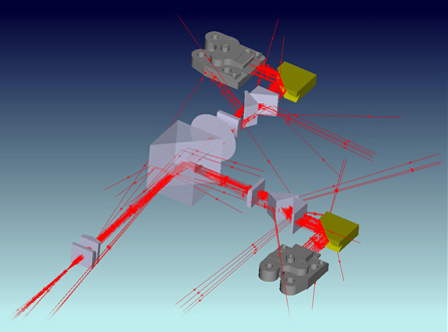

The complete solution developed by IK4-TEKNIKER consists of a high-powered diode laser incorporated into a machine designed for thermoplastics assembly. The device allows the parts one is intending to weld to be accurately positioned, and processed by means of a control system that allows three-dimensional handling. What we have here is an emerging technology with different applications, like the sealing of microfluidic devices used in the medical and biological diagnostics sector. Devices of this kind are used in DNA analysis and even have clinical applications. Likewise, the laser developed by IK4-TEKNIKER can be used to assemble microelectromechanical components (MEMS), which are used in medical implants like pacemakers or hearing aids.

The use of this technology in welding offers many advantages, like the absence of chemical adhesives in the sealing process (which could contaminate the product), the minimizing of the thermal effect on the welded spot, and the improvement in the quality and precision of the welding.

The project, funded by the Emaitek programme of the Government of the Basque Autonomous Community (region) and the Sub-programme of R+D Centres of the Spanish Ministry for the Economy and Competitiveness, is due to end in May this year, having been run for the last three years. IK4-TEKNIKER will be showing the prototype it has developed at the forthcoming Machine-Tool Biennial taking place at the Bilbao Exhibition Centre (BEC) between May 28 and 2 June.

To develop it, this Basque R+D Centre has had the collaboration of the Plastics Technology Institute AIMPLAS, which has developed the polymer materials used in the welding trials, and the Optical Techniques Group of the University of Cantabria (Spain), which has participated in tasks to do with the optical design and software.