NEWS

IK4-TEKNIKER is developing a new generation of ecological coatings for bearings that are highly fretting-resistant and can withstand high loads and temperatures.

As the mining industry usually has equipment situated in distant locations such as mountains or deserts, failures involving components may hinder normal operations at aggregate processing facilities and give rise to productivity complications.

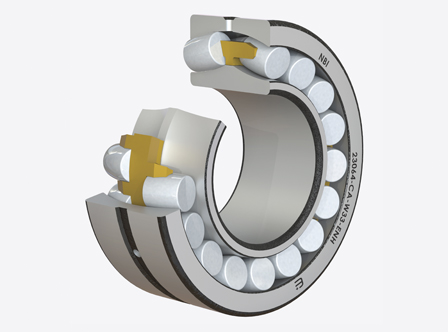

In the case of specific pieces of equipment such as vibratory screens exposed to the elements and to abrasive powder, they also have to withstand high levels of vibration, heavy loads and shocks which means that bearings are key elements as regards ensuring correct machine operation. Optimised bearing designs deliver longer in-service life cycles under the most demanding operating conditions.

However, one of the causes that reduces bearing life cycles as regards screens is a phenomenon called “fretting corrosion” or “contact corrosion” that produces wear and is sometimes followed by corrosive damage on surfaces with a certain degree of roughness.

So far, a number of solutions have been proposed to do address this problematic issue such as applying a PTFE coating or electrolytic chrome. These solutions, however, are currently being questioned as they are not environmentally nor health friendly.

It is in this context that the TERESINA project came into being. This main goal of this initiative, that IK4-TEKNIKER is currently working on, is to develop a new bearing concept for severe industrial applications that is environmentally acceptable and features improved properties with regard to fretting.

Surface engineering to deal with ‘fretting’

The technology centre, specialised in surface engineering, and specifically focused on tribology, materials and coatings, is working on the selection of materials, treatments and surface finishes that deliver an optimum response to fretting.

The ultimate aim is to develop efficient and ecological coatings that can withstand high loads and temperatures, that are highly fretting-resistant and present the added value of producing minimal environmental impacts.

Likewise, test protocols will be developed to identify and monitor wear mechanisms on bearings subjected to vibratory movements. Work will also focus on monitoring bearing wear and vibrations on test benches.

Developing cutting-edge technologies

The development of bearings with enhanced properties will be carried out by optimising designs and surface finishes in addition to using surface treatments based on the PVD technology (Physical Vapour Deposition), that will allow NBI Bearings, a company involved in the project, to access sectors related to vibratory screens used in mining and quarry operations and for which there are currently no alternatives to electrolytic chrome or PTFE.

As regards the procedure to be used, the technology centre's research team intends to coat the inner ring of bearings in contact with the shaft to provide fretting protection. IK4-TEKNIKER researchers, however, have not ruled out the option of applying PVD coatings to bearing races to improve their properties.

Likewise, and in order to identify and monitor wear mechanisms on bearings used on vibratory screens, with a specific focus on the fretting phenomenon, a number of tribological tests will be performed. Consequently, new bearing test protocols shall be developed to characterise materials and surface treatments, both at a test specimen and component level to learn more about the effectiveness of the products developed.

In short, the bearings to be developed within the framework of the project are intended to improve vibratory screen operation and lengthen maintenance-free intervals. They could also be valid for other applications operating under extreme conditions characterised by high loads and vibrations.