PROJECTS

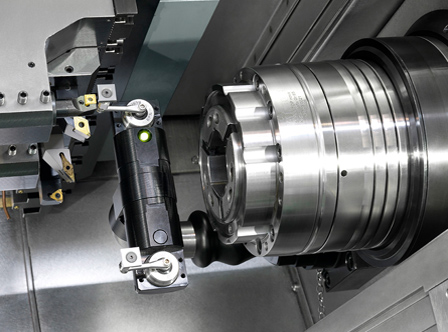

Machine-tool model, a multi-axis lathe for carrying out precision cutting-off and marketed by the company Unamuno. This development consists of an innovative design that reduces costs and speeds up production.

The development, which marks the start of collaboration between IK4-TEKNIKER and Unamuno, consists of applying a modular design to the latest advance in the "Máxima 65" machine range by Unamuno.

This new design incorporated into the "Máxima 9-65" model has common components that can be used in several models, an advance that helps to keep costs low and improve production times.

What is more, the "Máxima 9-65" has an innovative system to monitor tool life, a monitoring service and the necessary sensors to keep the machine working without it needing to be checked by an operator. The model also has a built-in system that sends alarm signals to the client's mobile phone, and a system of video cameras to monitor the machine more effectively.

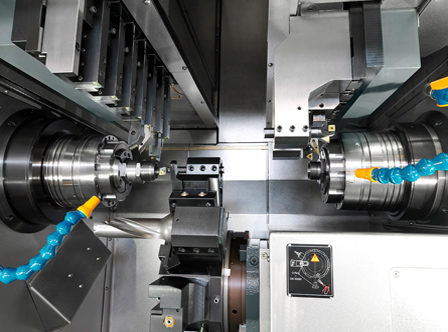

The "Máxima 9-65", developed through the collaboration between IK4-TEKNIKER and Unamuno, has been acquired by the British company Burnett & Hillman, which specialises in producing hydraulic adaptors to improve its production of hexagon socket plugs.

Thanks to the IK4-TEKNIKER and Unamuno technology, the British company has achieved faster production times that have resulted in a considerable improvement in results, in addition to the capacity of the machine to operate simultaneously by means of three tools.