PROJECTS

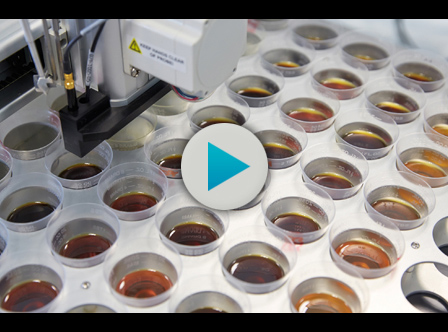

IK4-TEKNIKER has an advanced laboratory offering a comprehensive service with the capacity to analyse and establish diagnoses of at least 400 samples per day and provide a customised response within 24 to 48 hours.

Carrying out exhaustive monitoring of the physico-chemical, thermal and tribological properties of fluids for industrial purposes is essential to guarantee the properties of these substances. But it also contributes towards checking the overall state of the machinery, towards diagnosing possible defects and towards designing preventive maintenance strategies that are specific to each piece of equipment.

The IK4-TEKNIKER R&D centre has an advanced laboratory offering companies in the industrial sector a comprehensive service with the capacity to analyse and establish diagnoses of over 400 samples per day and provide a customised response within 24 to 48 hours.

The R&D centre’s premises allow a predictive maintenance-based diagnostic analysis to be made for heat transfer fluids (HTFs) and molten salts, and also for dielectric fluids, lubricants, greases and coolants used in a whole range of applications, such as air conditioning systems, solar thermal plants or heat exchangers.

What is more, IK4-TEKNIKER is capable of developing and improving industrial fluids through the selective incorporation of additives, such as nanoparticles and ionic liquids as well as the design and fine-tuning of advanced characterisation techniques to handle the new fluids coming onto the market.

The R&D centre’s techniques and initiatives have been validated by leading groups like AENOR and subjected to comparative studies with other laboratories.