INTERVIEW

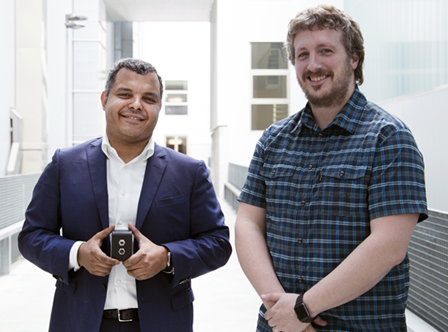

Eneko Gorritxategi and Edgar Martínez form part of Atten2 Advanced Monitoring Technologies, an IK4-TEKNIKER spin-off set up to develop and manufacture optical on-line monitoring sensors for fluids and lubricants used by machines and industrial processes.

During this interview, Gorritxategi and Martínez review the key developments that transformed this micro SME, born in 2012, into a company currently capable of offering a high performance product that has managed to attract the attention of companies such as Iberdrola and the Centre for Technological Development (CDTI), both of which became Atten2 shareholders in 2015.

1.- Atten2, established in 2012 as an IK4-TEKNIKER spin-off, has attracted the attention of several multinational corporations operating in the energy and automation sectors and has made a name for itself in a vast market. But could you name the key factors behind this success?

Although fluid monitoring on-line sensors were launched fairly recently (10-12 years ago), we have been able to develop an innovative solution that stands out thanks to its robustness, repetitiveness and reliability.

We have also managed to quickly adapt to market requirements by transforming the requirements presented to us by large-scale customers into functional and robust solutions. To a large extent, this has been achieved through the support received from IK4-TEKNIKER which, thanks to its structure and solid expertise in the field of R&D, has allowed us to significantly reduce lead times.

Furthermore, it must be stressed that the philosophy applied by Atten2 on how to address the market properly has been decisive. Whenever we make contact with a customer, we know it is essential that we fully understand their business needs to see how we can add value to their core activities and eventually deliver the right solution.

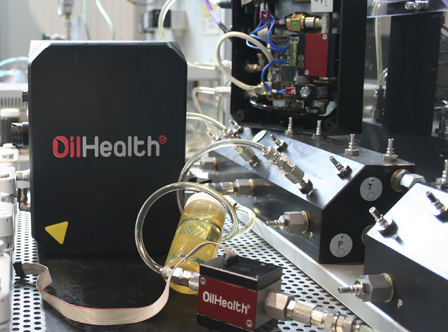

2.- Atten2 is currently marketing two solutions called, OilHealth and OilWear. How would you describe the differential value of these devices on the market?

The differential value of our devices is based on our capacity to offer customers answers with regard to the condition of their machines and also perform an assessment of any operating hazards based on the fluids used.

Technically speaking, OilHealth is a sensor that provides high-precision readings with regard to lubricant degradation levels. Unlike other pieces of equipment, the results delivered by this sensor offer a high degree of repetitiveness. The device, moreover, is very sensitive to minor variations in a lubricant’s condition and can therefore deliver estimates on a fluid’s remaining life cycle with a high level of certainty. Optical know-how is used to perform fast measuring operations adapted to each lubricant.

OilWear, on the other hand, analyses a machine’s condition by directly measuring wear levels. The sensor can provide this information as it measures the concentration of wear particles and performs a morphological analysis. This is how the root cause of any damage found can be analysed by discriminating between situations such as fatigue problems, wear produced by cutting stresses, slippage, corrosion etc. These functional features are fully supported by repetitiveness and high levels of accuracy.

OilWear is the only sensor of its kind currently available on the market that delivers such an extensive range of measurements and analyses by means of only one device.

3.- The project kicked-off in 2002, at IK4-TEKNIKER, and is the final outcome of several years of joint R&D actions in the field of sensors and lubrication. What has this cooperation been like with the technology centre since the idea originated and eventually materialised?

Atten2 was born thanks to a European project and IK4-TEKNIKER has been able to address the needs of a market increasingly interested in machine monitoring and in carrying out a project successfully in a number of work areas to eventually be able to manufacture these systems.

Lots of hard work then followed to develop equipment and carry out an industrialisation process. This meant that it was essential to properly address and identify customer needs to incorporate them to the resulting systems.

Nowadays, IK4-TEKNIKER development capabilities are fully in line with the needs of Atten2. This also means that joint R&D activities are highly satisfactory.

4.- The capital increase of your company in 2015 meant that Iberdrola became a shareholder of Atten2. What does the presence of such a large multinational corporation mean for a micro SME like yours?

The incorporation of Iberdrola to the Atten2 shareholder structure has not only provided the capital required for deployment, but has also given greater support and solidity to our company’s brand image. The degree of trust expressed by Iberdrola has served to open up the doors of a number of multinational corporations that would have otherwise been very difficult to access.

Iberdrola has also allowed us to implement validation processes in their business units. Any progress made in these processes will allow us to position our brand amongst other leading manufacturers of fluid sensors in the market at a global level.

This agreement does not only allow us to do business with them, but also provides us with us a source of learning and knowledge linked to the energy sector.

5.- The company has experienced meteoric growth since it was established 3 years ago and is now reaching out to countries like China, USA, Korea, Italy and Australia. What is your current outlook and could you describe your short/medium term prospects?

Our short/medium term goal is focused on playing an outstanding role in key sectors such as conventional energy, wind power, automation and capital goods.

But Atten2 also believes that the market’s future will be based on the digital transformation process currently unfolding in the industry and on using information as a key element to deliver value.

This is why we are adapting our value proposal so that our organisation can be positioned fully in line with the market’s expectations and needs.

6.- Atten2 is already considering other markets such as the agro-food industry. How would you rate your presence in this sector?

Both the agro-food and biotechnology sectors are characterised by natural links with the know-how and development possibilities that Atten2 offers. These markets are very interesting and we hope to address them in the medium/long term, although our company is still young and this means that we must first consolidate our current actions before moving into a new phase.