NEWS

Flexible robotics to feed parts to a machine, additive manufacturing and self-checking solutions for large machines are only a few examples of what IK4-TEKNIKER will be showcasing at BIEMH 2018.

As from May 28, IK4-TEKNIKER will be present at the Bilbao Exhibition Centre (BEC) to participate in the 30th edition of the Machine Tool Biennial (BIEMH). The technology centre will have its own exhibition space situated in hall 1, aisle C22, to display its developments for the machine tool sector.

In order to address the challenges faced by Basque companies in this sector, IK4-TEKNIKER is currently working on a number of highly innovative technologies geared towards manufacturing smart machines that provide digitised manufacturing environments. In the course of the trade fair, therefore, the technology centre will showcase specific solutions related to flexible automation, modelling and machine-process simulation (virtual machines), machine status (Health assessment), process optimisation and machine fleet management.

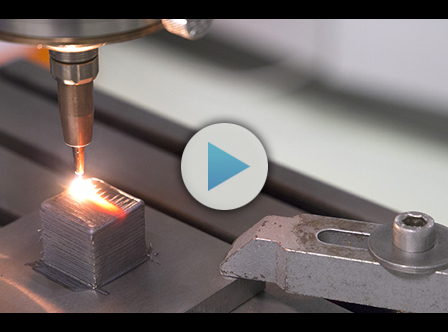

Furthermore, the technology centre will present its global offer in terms of laser technologies that has given rise to the so-called Laser for Manufacturing Lab, an initiative that delivers solutions designed to meet the requirements of extremely demanding sectors.

The technical proposal embraces different manufacturing processes; the design and production of equipment and components; additive manufacturing; inspection and measurement, consultancy and training in the field of laser technology.

The third development that IK4-TEKNIKER will present at the exhibition centre is a patented solution (“Integrated multilateration for machine tool automatic verification”) that automatically checks the geometry of a machine tool throughout its entire work volume by incorporating a Laser Tracker to the machine itself as if it were just another tool.

This allows the technology centre to cover any needs connected to automatically checking large machine tools that must guarantee a degree of accuracy under 0.1 mm throughout their entire work volume at all times.