PROJECTS

IK4-TEKNIKER is developing digital twins that will improve the development of control software for equipment and prevent malfunctioning in early testing stages. The technology centre will present the virtual commissioning methodology at the upcoming edition of the Basque Industry 4.0 conference by describing a specific case.

Cyber physical systems (CSP), artificial intelligence, the Internet of Things (IoT) or Big Data, among other concepts, are currently being rated as disruptive technologies when addressing “Industry 4.0” in a context that is becoming increasingly demanding and competitive. Consequently, simulation tools are being applied to a larger extent to increase the efficiency of production processes with “Digital Twins” as one of the trends that has been reinforced over time.

Digital twins are virtual equipment models used to better understand and predict the performance characteristics of their real/physical equivalents. They are used throughout the entire life cycle of equipment to simulate, predict and optimise operations prior to investing in prototypes and physical equipment.

It is in this context that IK4-TEKNIKER is currently working on developing digital twins to test, correct and validate equipment software prior to having physical/real equipment available to perform debugging and which is a very interesting option when equipment is either scarce or inaccessible for commissioning.

During conventional development processes of equipment, all subsystems (mechanical, electrical, control, software, etc.) are developed independently and this means that subsystems can only be tested and validated once advanced development stages have been covered.

Control software, in fact, is usually the last link along the manufacturing and assembly line. This explains why testing and validation timing for this subsystem usually focus on anomalies arising throughout a project.

This risk of causing severe damage that could potentially affect equipment whenever software is tested makes it difficult to run tests covering all possible operating and error conditions.

IK4-TEKNIKER applies a methodology called virtual commissioning that uses virtual models to test equipment control software prior to being available (connection and virtual commissioning of equipment) so that tests can be run in earlier stages of a project to detect errors in advance. This makes it possible to reach the commissioning phase with fully debugged control software.

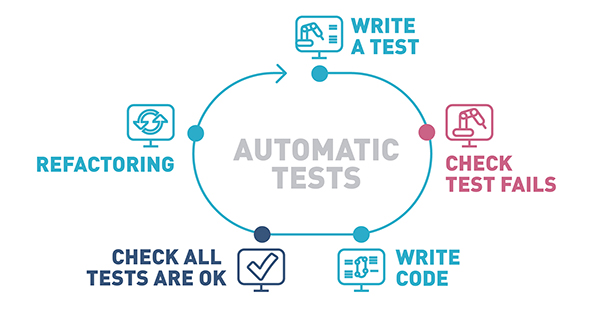

In summary, when applied to equipment software programming, this methodology offers a large number of improvements that minimise commissioning time and potential accidents. It also allows for automatic testing and repetitive errors are avoided with regard to software quality and improved software maintainability.

Figure. Test-driven programming methodology

The technology centre will apply this methodology (virtual commissioning) to develop and commission control systems for the Large Synoptic Survey Telescope (LSST), the world’s most advanced telescope to be commissioned in Chile in 2020.

More specifically, the technology centre will install a hardware in the loop system (simulations that provide an interface between the plant model and the integrated system under test) for the telescope’s two main controllers in addition to an automatic testing system to minimise the amount of time required to commission the telescope at Cerro Pachón, in the Chilean desert of Atacama and to avoid potential damage affecting the telescope.

This work will be presented under the title “Models for simulating the development and commissioning of systems -Virtual Commissioning-“ at the upcoming edition of the Basque Industry 4.0 conference that will take place at the Bilbao Exhibition Centre (BEC) in Barakaldo on November 20-21.