Tekniker has an innovative solution that saves time and improves productivity in industrial processes involving texturizing, micro-drilling, cutting or machining.

In the market there are nowadays fixed optics laser heads and scanners that are used in manufacturing processes. As far as the latter are concerned, those most commonly used are the so-called galvanometric scanners.

Although these systems are extensively used in the industry (for laser marking, for instance), they are barely feasible in high productivity processes and/or whenever low added value products are involved.

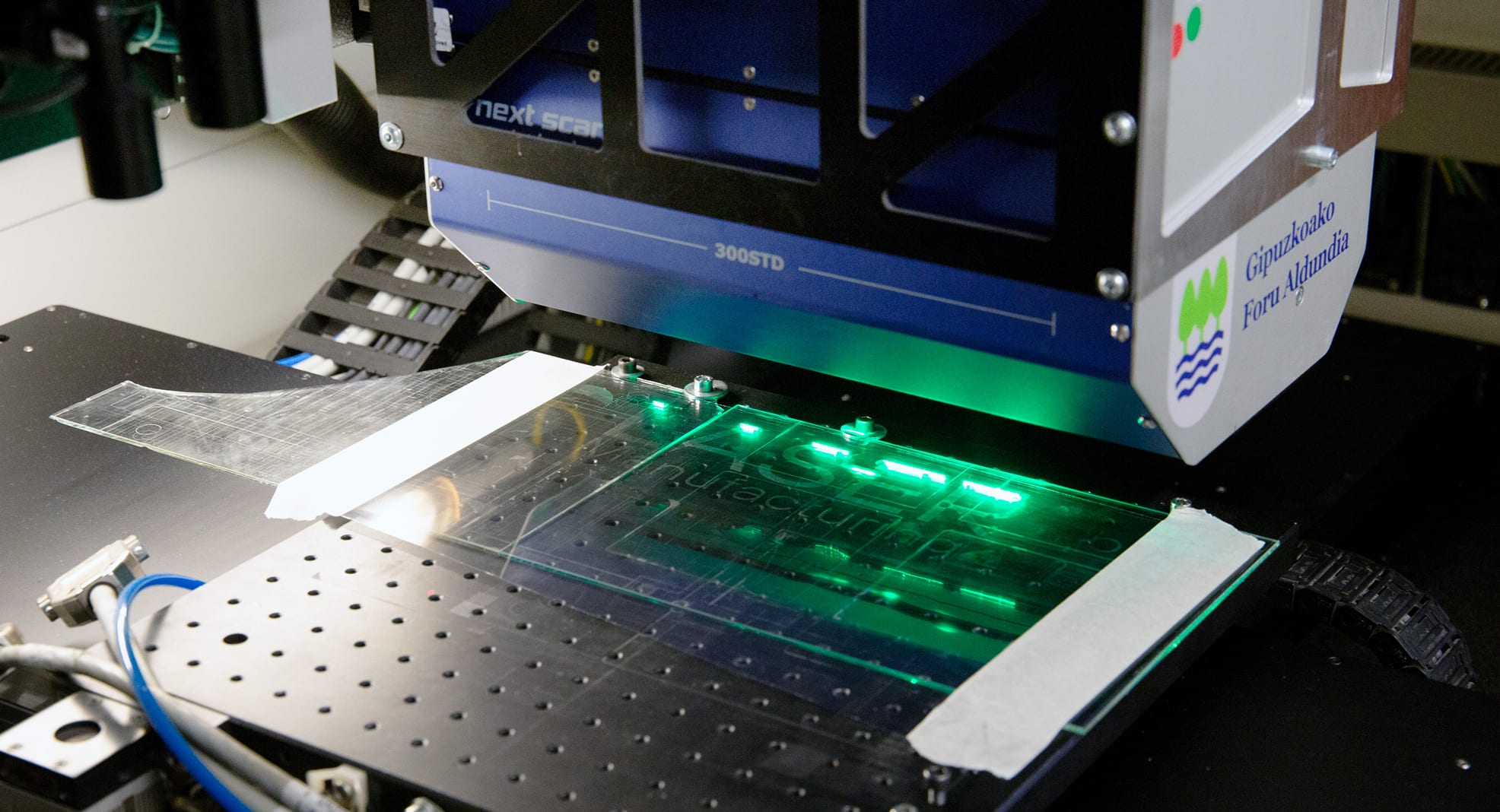

In this regard, one of the most innovative solutions the market has to offer is related to polygonal scanners that run at higher speeds, reduce running time and achieve higher levels of productivity. Tekniker, therefore has acquired one of these new scanners, providing itself with a singular equipment, unique in Spain, that contributes to the progress of the technologies application that require these demands.

It is a laser technology with a spot that rebounds on a polygonal mirror from where it is reflected. The rotation of this mirror allows the laser to trace a line in such a manner that by moving the specimen it becomes possible to process perpendicularly relative to the line.

The main unique feature of this system can be found in the guiding system used for the light beam. Given that mirrors can rotate at very high speed settings, relative movement between the sample and the beam can reach a maximum of 100 metres per second.

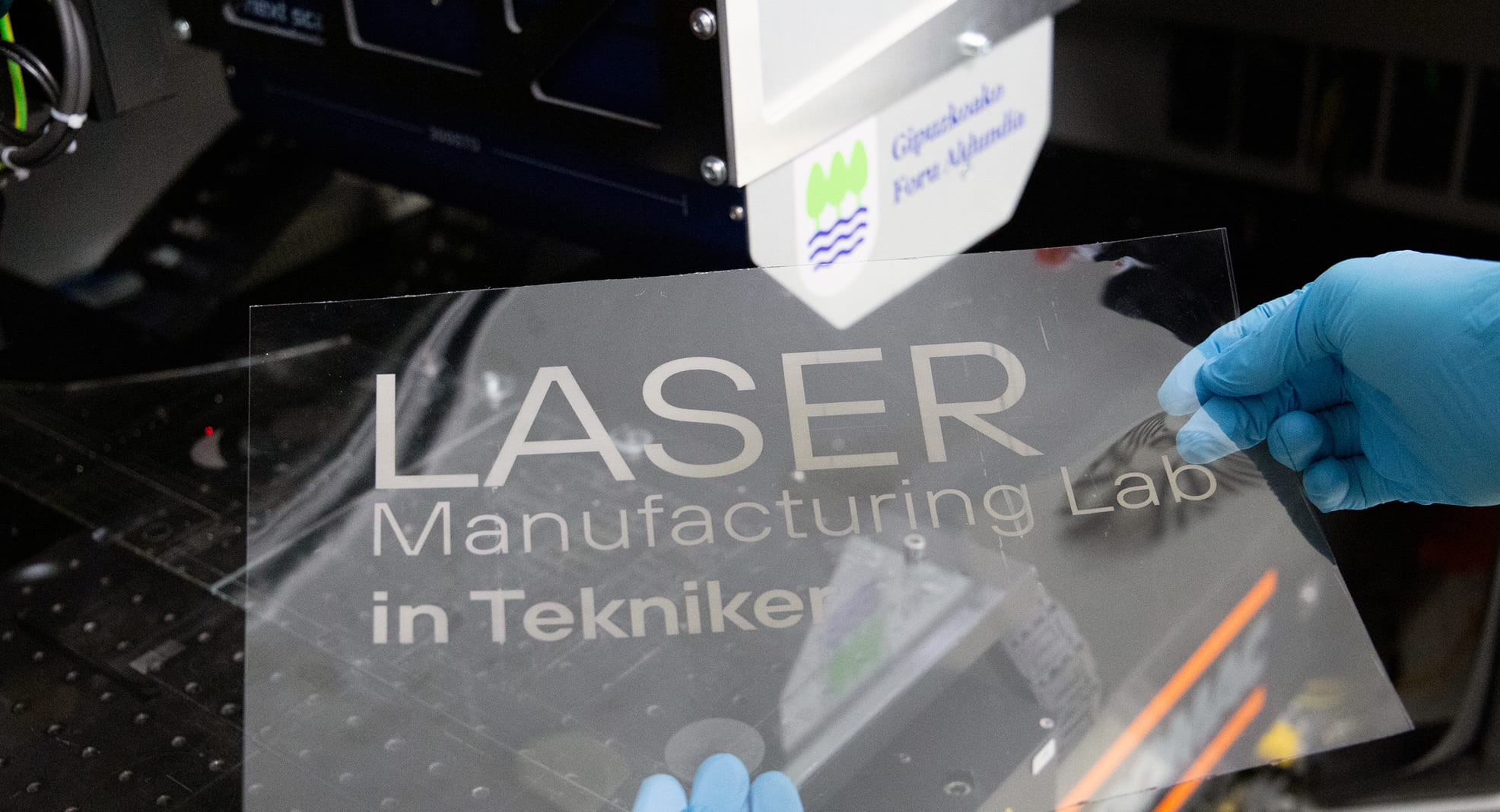

For instance, a 1m2 surface can be texturised by laser in less than five minutes compared to conventional systems that can take up to an hour. In the case of lower added value products, this is what makes laser processing more feasible.

This manufacturing system recently adquired by Tekniker will allow the organisation to offer the industry (via its Laser Manufacturing Lab) unitary services and pre-series to be installed in production processes as well the development of new innovative processes.

Funding has been received from the Provincial Council of Gipuzkoa for this equipment.