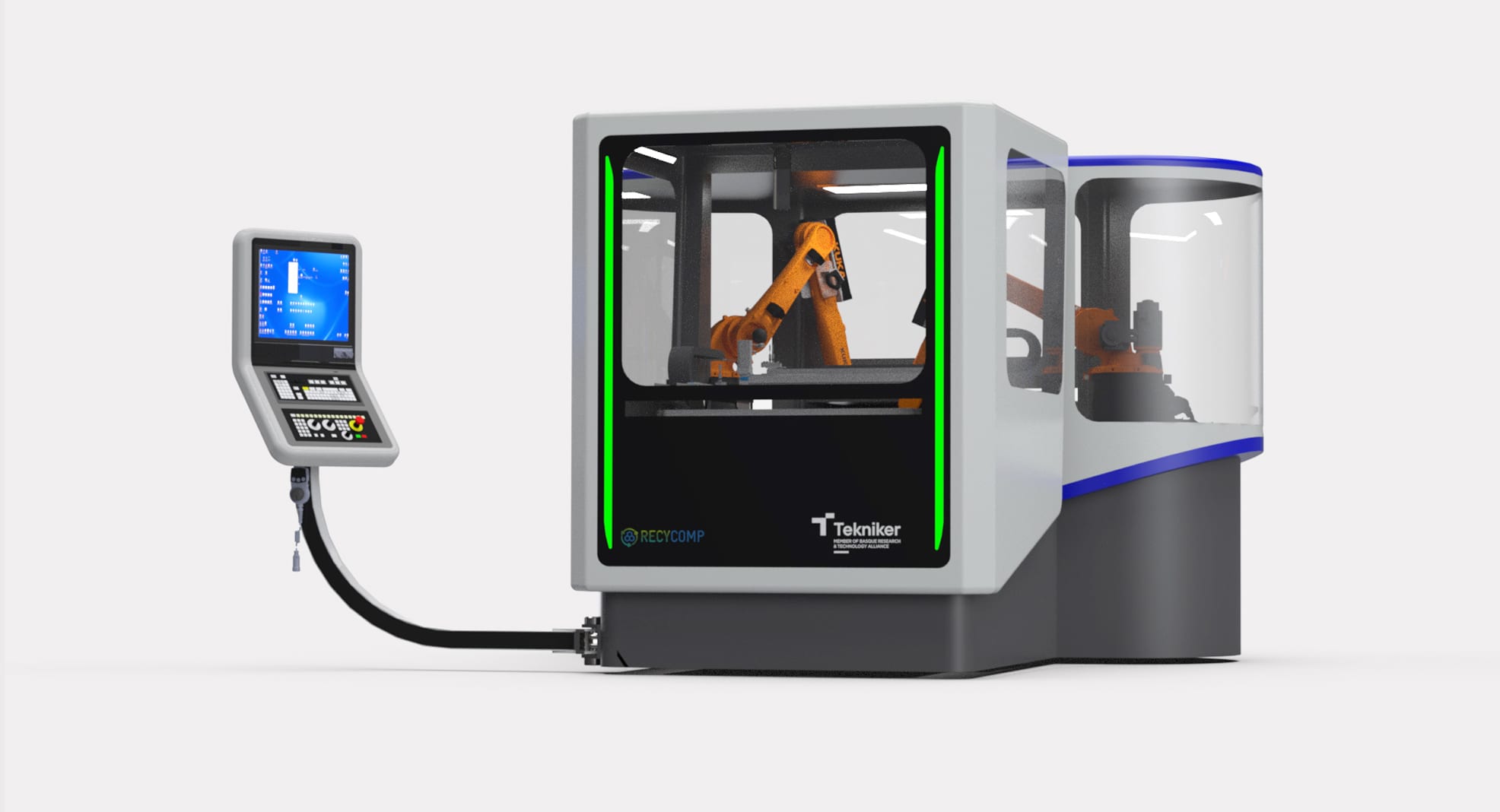

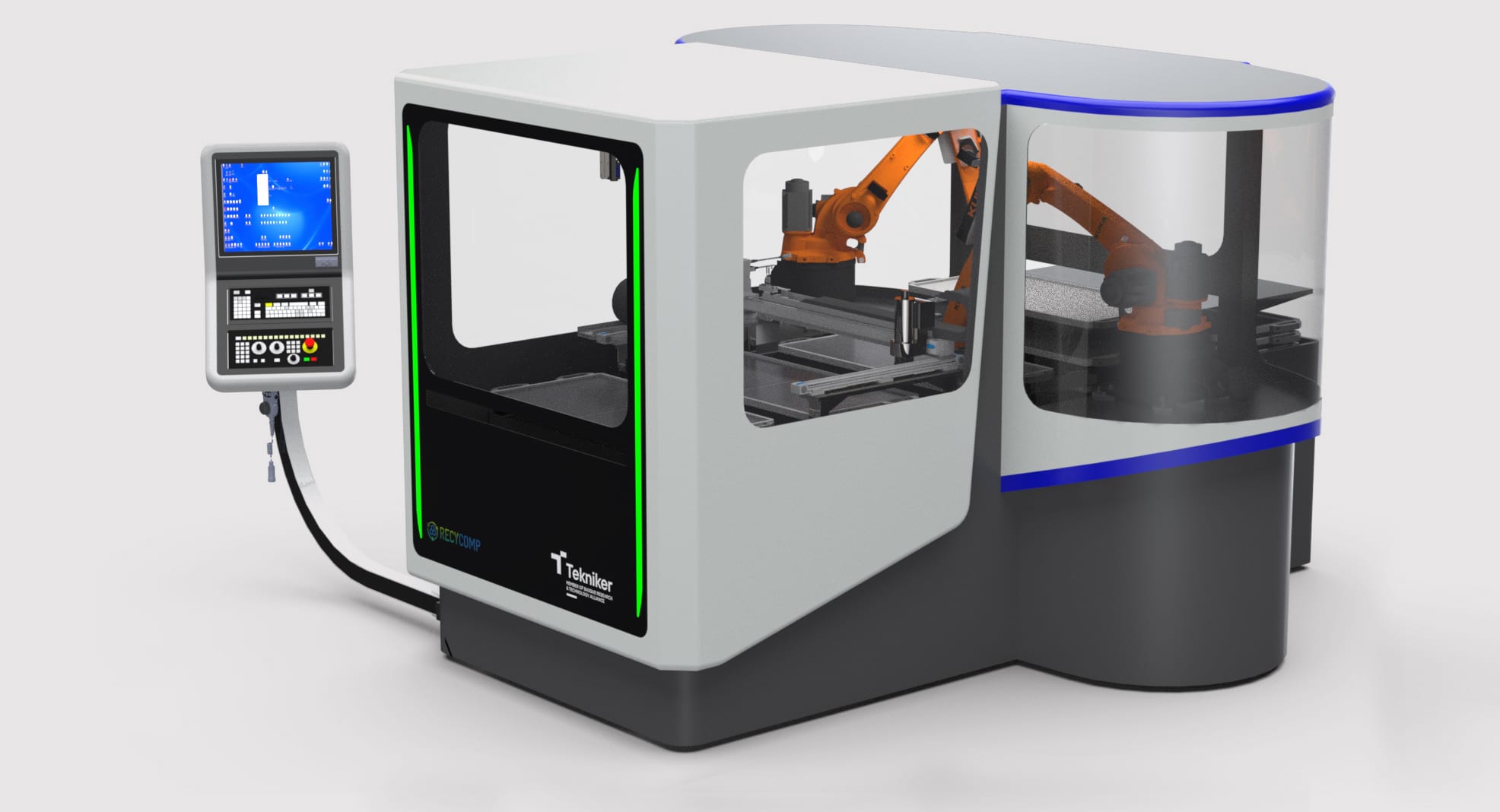

Tekniker is currently leading the RECYCOMP project to develop a machine that will allow surplus materials resulting from industrial processes be used again in the aeronautical sector.

A number of policies focused on the circular economy, recycling and environmental concerns promoted by the European Union and the Basque Government are allowing the industry to move in the right. The implementation of economically profitable production resources and processes that allow materials to be used again must be given priority to further the demand for recycled materials in the market.

The RECYCOMP project, led by the Basque technology centre Tekniker, a member of the Basque Research and Technology Alliance (BRTA), intends to make further progress with regard to introducing sustainable production resources and processes specifically focused on surplus materials containing pre-impregnated unidirectional carbon (PREPREG) produced in automatic or manual rolling processes for the manufacture of components in sectors such as aeronautical business where surplus materials are either taken to landfills or incinerated and only give rise to environmental problems.

It has been estimated that this initiative, under the umbrella of the European Clean Sky 2 call, will finish towards mid 2023 and allow further progress to be made in terms of analysing and monitoring the behaviour of recycled materials to be used at a later stage to manufacture functional components for the aeronautical industry.

In order to so do, Tekniker will contribute its expertise associated with a number of technologies to design and build a machine that is able to recover and reuse PREPREG surplus materials. Said technologies include the development of special machinery, mechatronics, automation, robotics and artificial vision.

The technology centre will also perform mechanical testing to monitor how recycled materials behave in test specimens subjected to mechanical testing to compare their degree of resistance relative to the figures obtained with non-recycled materials. Eventually, it will become possible to use these materials to manufacture non-critical components such as internal parts for seats, overhead bins, etc.

The aim of the RECYCOMP project is to have a prototype ready by September 2022 to be commissioned at the facilities of the manufacturer and Topic Manager Leonardo Aircraft Division in Naples (Italy).

RECYCOMP project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 886967.

Further information HERE.