INTERVIEW

Fco. Javier Fernández de Retana is the Director of Institutional relations at Aernnova, a company that designs and manufactures aerostructures such as wings, stabilisers and fuselages in metal and composite materials for leading OEMs. During this interview, Fernández de Retana underscores the importance of collaborative work between the company and the technology centre to achieve excellence and develop innovative products and services.

1.- Aernnova is a reference company in the design and production of aeronautical components that owes most of its success to the fact that you are deeply committed to digitising your processes. How are you addressing this approach in terms of Industry 4.0?

The aeronautical business is characterised by developing high added value products that are safe and meet high quality standards. Our aim has always consisted in achieving technical and operational excellence based on the intrinsic features of our end products.

To achieve this goal, Aernnova believes it is essential to use a number of new technologies that are being introduced on a massive scale by the Industry 4.0 revolution. Apart from Sensoring Digitisation we are also talking about Big Data, Augmented Reality, Cloud, Predictive Quality, Collaborative Robotics, Additive Manufacturing and, of course, Cybersecurity.

We are firmly committed and are addressing this challenge because we know it is the path we must follow in the future.

2.- Aernnova has been a member of the IK4-TEKNIKER Governing Board since 2013. Could you describe what this collaboration has been like over these years?

Our company is Basque and we're very proud about out our involvement as Trustees on the Boards of several members of the RVCT (Basque Network of Science & Technology), one of which happens to be IK4-TEKNIKER.

There are several highly relevant lines of technological cooperation with IK4-TEKNIKER.

On the one hand, new drilling solutions for composite materials and metal and micro-perforation and texturing of metal parts, particularly titanium.

On the other, additive manufacturing technologies. And, finally, several technological developments to be implemented on specific and highly customised applications connected to in-house production processes.

Mention must also be made of collaborative efforts already in progress within the framework of the HASI project by Aernnova to develop Industry 4.0 technologies and generate new manufacturing systems that are flexible, smart and efficient.

3.- To take a case in point, it was in November when you presented a joint approach to develop laser solutions that will enhance the competitiveness of the aeronautical business. How much value would be added on for Aernnova if your R&D strategy were placed in line with that of a technology centre?

To achieve further growth, Aernnova must win new contracts based on developing innovative products and services to showcase our outstanding technological capabilities.

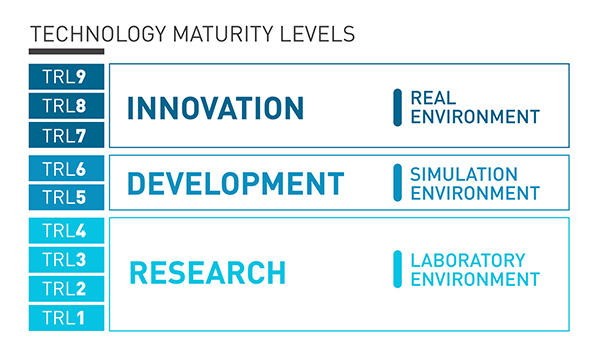

To this end, we have released a concept called "Extended Technological Business", an instrument that allows us to act as a driving force for universities and technology centres in the RVCT, for collaborative work by projects, mainly in low TRLs.

Technology centres, in particular, complement Aernnova in TRLs 4 and 5 by linking-up with universities situated in the lowest TRLs.

4.- Your quest for excellence and high added value engineering has made you extend your activities to become a reference in the design and production of aerostructures at a global level. What sort of challenges will you face in the future? How significant will joint projects be when carried out with other companies and technology centres?

Aernnova's main challenges are focused on becoming one of the world's leading Tier 1 companies and a preferential supplier of its main customers: Airbus, Boeing, Embraer or Bombardier, among others.

To walk down that path, we obviously need to have operational excellence and continuously improve our technological capabilities alongside other companies, universities or technological centres to maintain what is an essential line of work for the company.