THE EXPERT'S VIEW

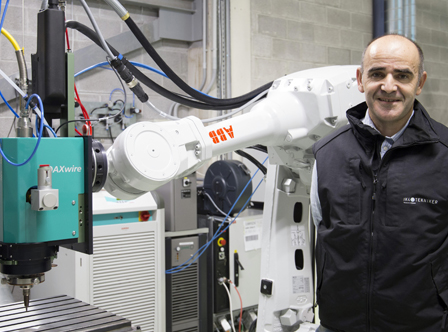

The implementation of automation and industrial robotics in different sectors is changing production processes. Therefore, IK4-TEKNIKER works alongside companies in their search for the automation solution that best suits their needs.

Artificial intelligence alone will cause an additional increase in world GDP of 15.7 billion additional dollars in 2030, 6.6 million (42%) will be generated as a result of increased productivity and 9.1 million due to the effects on consumption.

The world economy will be 14% higher in 2030 as a result of the effects of artificial intelligence. This is reflected in the report ‘Sizing the price. What is the real value of AI for your business and how can you capitalize’, written by PwC.

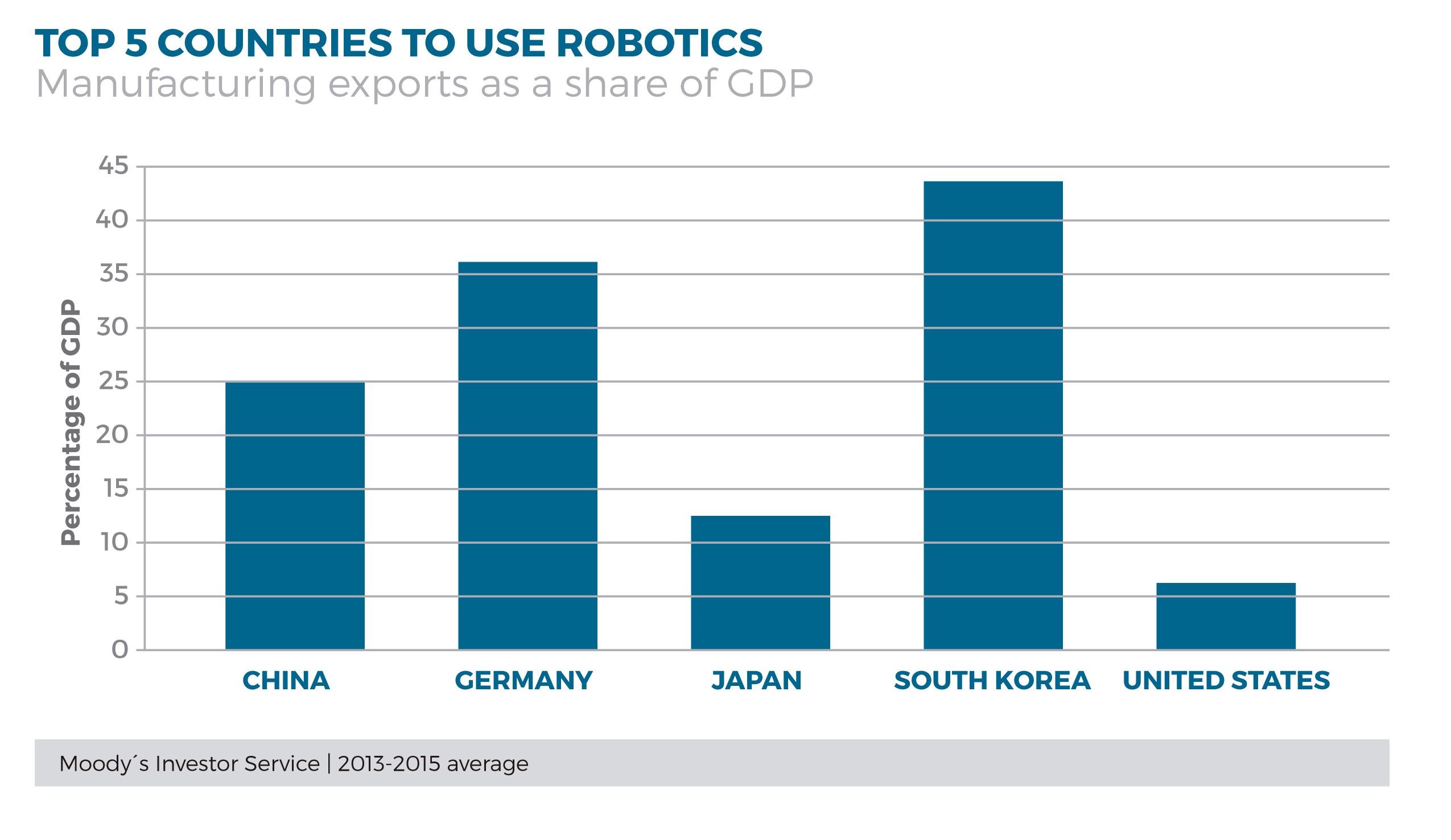

Worldwide, Japan and Germany are at the forefront of robot automation. The emergence of automation and digitalisation processes in their production systems has not only given them an acceleration rate additional to their economies. The turbocharging that robots have added to their production tasks has also created new jobs and spurred the foreign sector of both countries, which gives them an even more hegemonic status as exporting powers.

The two powers lead in robot automation; the fourth industrial revolution. So much so that their robots have begun to minimise their impact on employment.

Several recent studies review the beneficial effects of productive robot automation. One of them is signed by the rating agency Moodys, which sees the European economic engine and the most industrialised economy in Asia as the most advantaged students in the robot revolution. In both cases, say its experts, the automotive industry has been the pioneer, although the process has spread in such a way that it has managed to create its own sector, that of robotic technology, which could modify the family income if, for example, as is already happening, digital automation reaches households to produce individual energy.

Source: Bloomberg. TOP 5 countries that use robots.

Our vision of industrial automation and robotics

According to the article “Reflections on industry 4.0 from the Basque case”, the Basque Country industrial fabric has great capacity for integrating the various technologies linked to the manufacturing activity, such as automation and process optimisation, a strength which is developed in companies and in engineering.

The technological needs of the manufacturing companies, in which robot automation implementation enables them to compete successfully in global markets, are met by proprietary and external engineering resources, also with the support of an extensive network of technology centres and universities, especially in terms of R&D activities, since they are at the forefront of technological knowledge, as evidenced by their participation in European top-level programmes. Accumulated technological knowledge in the Basque Country varies, therefore, from more conventional metalmechanic aspects to those of an advanced ICT nature, considering that access to the technology needed for the transit to Industry 4.0 would be guaranteed.

However, the development of Industry 4.0 requires an interdisciplinary and holistic vision.

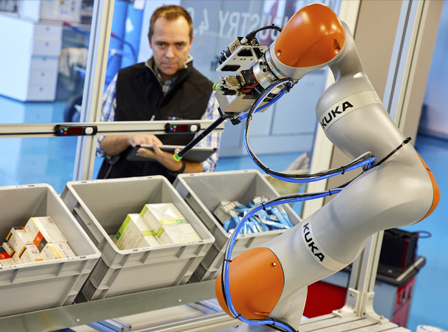

In any case, when talking about automation, you cannot talk about an overall automation solution. A solution must be detailed for a specific approach, using technologies as diverse as artificial vision, advanced sensorics, industrial communications, robotics, PLCs, CNCs, etc. Each approach may have one or more solutions, but always aiming to find the most appropriate in each case. The needs and requirements that each client may have differ as much in the technical/technological as in the economic aspects.

When the application demands it, robots offer more flexible and reconfigurable solutions in the framework of automation. The role of industrial robotics is key since it has considerably transformed some of the most well-known production processes such as welding, palletising and packaging, among others.

One important aspect to take into account before addressing an automation process is the return on investment that is expected to be obtained as a result. Automation can result in a significant investment, and it is necessary to assess all aspects from the economic, technological, etc. point of view before launching the process.

In this sense, a technological and overall feasibility study must first be carried out that provides an understanding of the level of automation required to guarantee the best solution. The simulation and design, the development of a pilot solution, assembly and commissioning and continuous support for the correct operation of the system, and its updating and evolution, are key to improving the effectiveness of the processes, optimising the operation, reducing the times and costs, and increasing reliability.

This process would have the following scope in each of its phases:

Technological prospective: Diagnosis of the impact of automation trends in the area of interest. The objective is to reduce technological risk and anticipate environmental changes.

Feasibility study: A comprehensive study of technical and economic feasibility totally independent and customised to implement a feasible automation solution to meet the requirements proposed. Independent approach to the solution with a specific analysis of the need for robot automation.

Simulation and design: Models, technical documentation and manufacturing plans to achieve the requirements established in the automation solution.

Development of pilot solution: First functional implantation. Validation of the solution: Trials and tests. Optimisation of the solution for industrialisation.

Implementation and commissioning: System operating according to the stipulated requirements with the corresponding technical support documentation.

Update and follow-up: Continuous support for good operation of the system, its updating and evolution.

Bibliographical references

Navarro, M., Sabalza, X. (2016): Reflexiones sobre la industria 4.0 desde el caso vasco. Ekonomiaz: Revista vasca de economía, ISSN 0213-3865, Nº. 89, 2016, págs. 142-173

Herranz, D. (11/09/2017): Japón y Alemania fían a la robótica el sostén de sus sistemas de pensiones. Público.es

Redacción COMPUTING (20/07/2017): La Inteligencia Artificial será el motor del PIB mundial. Computing.es