NEWS

The project has focused on developing smart, resilient and safe robotised solutions for assembly and intra-logistic operations in the automotive sector and capital goods business.

Building environments that are more competitive in terms of industrial manufacturing. This is the goal of the ROBO-PARTNER project in which IK4-TEKNIKER has been involved and is focused on developing know-how to produce collaborative automation systems for assembly operations that combine the essential skills of expert workers with those of robots with regard to strength, speed, repeatability and accuracy.

In order to achieve this goal, a solution based on industrial robots has been developed that allows human beings and robots to collaborate without requiring any physical barriers. More specifically, the project is focused on developing several industrial applications connected to moving heavy loads on site or collaborative assembly operations for household appliances.

Consequently, a number of advanced strategies and safety elements have been designed that have made it possible to build barrier-free work spaces inside which robots may work with persons thanks to advanced movement monitoring strategies.

Intuitive interfaces have been developed, moreover, to facilitate cooperation between robots and workers during assembly operations by means of voice recognition devices that provide a more natural interaction.

This know-how has already been validated in several industrial environments such as the automotive sector, for instance, where there is a robot in operation whose task consists in fitting a rear axle component collaboratively with workers at a Turkish automotive firm called Tofaş. This significantly improves on-the-job ergonomy.

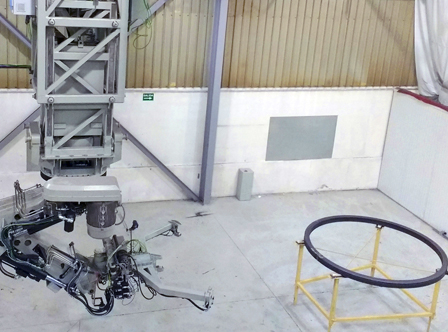

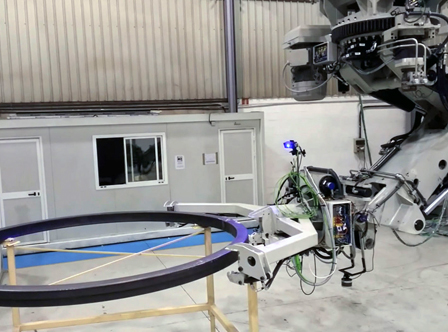

There is a second demonstrator at JATORMAN, an engineering firm, focused on transporting large parts as well as a third and final demonstrator in the household appliances sector that is currently being used to validate this solution in assembly operations involving a component fitted on Electrolux fridges.

Together with IK4-TEKNIKER, the Navarra-based company JATORMAN has also been involved in this project by offering its capabilities in terms of automated handling and erection systems used to move large loads by means of the Hércules robot.

The Hércules robotic arm was developed in collaboration with IK4-TEKNIKER, with the latter providing all the smart equipment required to achieve full integration in collaborative environments.