THE EXPERT'S VIEW

The autonomous communities (regions) that exceed the Spanish average with over 6.75 SMEs per 100 inhabitants are Catalonia, the Balearics, Community of Madrid, the Basque Country, La Rioja and Galicia. If reference is made to the number of small and medium-sized enterprises, the same ranking is more or less repeated in both categories for every 100 members of the labour force and 100 of the employed population, with Catalonia and the Basque Country being ranked with over 15 SMEs/100 members of the labour force and Catalonia and Extremadura with 21.01 and 19.19 SMEs/100 members of the employed population, according to data of the Central Register of Companies (DIRCE).

The overall conclusion of the analysis of the figures and the business indicators of Spain is that the business base has a relatively stable configuration around small and medium-sized enterprises, the crisis notwithstanding.

In general, all the sectors have been adversely affected in recent years with a significant fall in the number of large companies and SMEs. That being the case, the context of the Basque Country is as follows:

Of the 158,538 companies in the Basque Country, 158,303 are SMEs (0 to 249 employees), which is 99.85% of all the companies in this autonomous community. 94.18% are micro-enterprises (0 to 9 employees) of which 52.02% are enterprises without employees. The number of large companies is above the national average: 0.15% as opposed to 0.12%. In this group it is the provinces of Vizcaya (0.17%) and Alava (0.15%) which are the most prominent.

The industrial sector, which accounts for 8.54% of the total number of companies, is basically manufacturing with its activities focussing on the manufacture of metal products, the processing of food and drink products and publishing, graphic arts and reproduction.

If one looks at the indicators linking the number of companies with the labour force and employed population in the sphere of reference, it can be seen that in the Basque Country the average number of SMEs per 100 inhabitants is 7.22; for every 100 members of the labour force this rises to 15.49, and for every 100 members of the employed population the figure rises to 18.42.

The evolution in enterprises between 2002 and 2011 shows that in the Basque Country there was a net growth of 3,840 enterprises, which signifies an increase of 2.48%, way below the Spanish average (13.58%). The province where enterprises saw the greatest growth during this period is Álava (4.83%), whereas Gipuzkoa saw a negative variation of -0.98%. With respect to the recent evolution, in the Basque Country, between 2010 and 2011, there was a net reduction of -6,517 enterprises, nearly all of them fitting into SME typology (-6,521) and within this category, they were mostly enterprises without employees (-5,302) and enterprises with between 1 and 9 employees (-1,058). Enterprises with over 250 employees is the only stratum that is growing (1.73%).

By sector, they all saw a reduction, with construction experiencing the biggest absolute reduction (-2,305 enterprises) and relative reduction (-8.23). Industry had a lower absolute negative variation (-430 enterprises).

In this context, the incorporation of innovation processes into SMEs and micro-SMEs is vital to guarantee that they remain on the market in the long term.

Today, one still frequently hears about the reluctance by some small enterprises when it comes to collaborating with an R&D centre, because they often think such centres are geared towards large companies, large corporations or large industrial groups. But nothing could be further from the truth. In fact, if one goes right back to when IK4-TEKNIKER emerged back in the 1980s, its involvement with the enterprises has been and continues to be total, because it was in fact a group of small enterprises which set up and founded IK4-TEKNIKER, because they needed technological laboratories.

That spirit has continued over the years and continues to grow to the point where "generating and transferring technology to SMEs and micro-SMEs", is already in our DNA. So much so that about 90% of our clients belong to this industrial segment.

Furthermore, the involvement in and relationship with enterprises continues to be very substantial, as made clear by our indicators for 2013. We produced a total of 88,465 reports and certifications for a total of 1,625 companies in our advanced technological service laboratories alone; these were in the spheres of comprehensive lubrication management, diagnosis of causes of faults, and dimensional metrology.

Our contribution to enterprises goes hand in hand with technology and a high degree of specialisation. At IK4-TEKNIKER we have a whole range of technological capabilities that we put at the service of SMEs and micro-SMEs and which allows them to improve their competitive position. We need only two things from the enterprises themselves: “concern and a spirit open to collaboration".

There are many success stories of small enterprises which have entrusted their R&D projects to us, but I would like to draw attention to that of the enterprise ORGUISA as it is particularly illustrative.

Success story of a micro-SME: DECOLETAJES ORGUISA

ORGUISA is an enterprise located in the Basque town of Eibar and has 5 workers; its main activity centres on precision cutting for the automotive, white goods and locksmith sectors, etc. Its work ranges between Ø1 and 34 mm in various materials (steel, brass, aluminium, stainless steel, etc.).

The first concern they raised with us was the possibility of accessing new markets with new technologies, bearing in mind that their human resources were very limited. “There are only 5 of us, we are keen… but only 5,” the CEO Isidro Ormaetxea assured us.

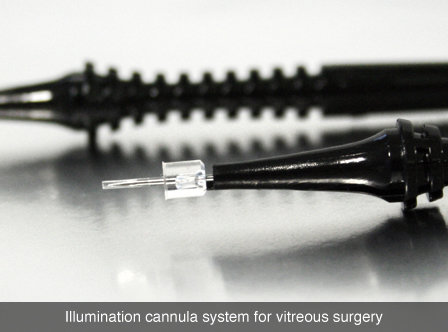

At IK4-TEKNIKER we spotted an opportunity to manufacture a device for the biomedical sector: a “Light Trocar”, a device that guides light to the back of the eye.

Then the possibility of taking up this new challenge was put to ORGUISA and the first steps were designed to adapt its technological capabilities to the initial designs of the trocar.

During the process the designs were simplified and improved so that part of the device is produced in Vancouver (Canada) and the rest in ORGUISA, which has led to a considerable reduction in the cost of the device.

Technologically, the difficulties for ORGUISA were linked to precision and the material to be machined, as it is an innovative, new-generation material. The component has a diameter of 3 mm and is 5 mm long, but it has details with thicknesses of 5 microns. The material also has complications as it is a biocompatible medical polymer with optical features (PMMA).

The collaboration between ORGUISA and IK4-TEKNIKER has made it possible to manufacture a prototype for eye surgery or vitrectomy destined to improve reliability in surgical operations.

IK4-TEKNIKER’s aim is to collaborate with enterprises, be they large or small, since size is not an issue for the impact of innovation.

All the statistical data on number of enterprises, sectors, etc. are based on data from the Spanish Ministry of Industry, Energy and Tourism. General Directorate for Industry and Small and Medium Enterprises. General Register of Companies (DIRCE) SME Statistics. Evolution and Indicators, Publ. March 2013.

www.ipyme.org