PROJECTS

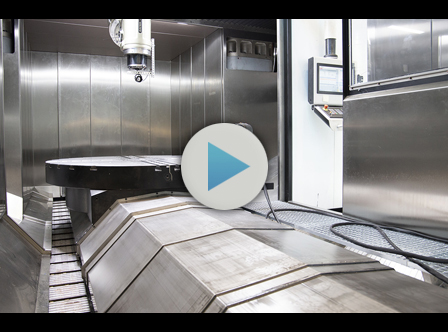

As machine tools are getting increasingly bigger, IK4-TEKNIKER is working to develop technology focused on volumetric verification and compensation to address the constraints posed by procedures currently in use.

The concept of volumetric verification and compensation was first introduced in 1973 by P. A. McKeown and J. Loxham. It was been systematically applied over the years first by coordinate measuring machine manufacturers and later by machine tool companies to improve overall machine accuracy.

But both the methodology used and, above all, the measuring systems that have materialised everything, have evolved significantly to offer a robust range of solutions used nowadays.

The rigorous verification of machine tool geometry and volume is becoming increasingly more difficult as machines grow in size. The use of traditional measuring systems such as interferometry, perpendicularity patterns or electronic level gauges do not provide a complete vision of a machine’s geometry as they cannot deliver the high degree accuracy demanded by the aeronautical sector, for instance, and cover the entire working volume of production resources.

With a view to overcoming the limitations associated with these procedures, IK4-TEKNIKER is currently developing a technology focused on volumetric verification and compensation for large machines that has evolved over time.

Initially, the technology centre developed a proprietary volumetric verification solution based on in-house software equipped with laser tracker technology and electronic level gauges.

Using this first system as a basis, a faster verification solution was developed by simultaneously combining several measuring systems and reducing the amount of time required by 75%. This approach, however, was not feasible from an economic viewpoint as the use of four measuring systems simultaneously is associated with significant costs.

In the final stage, however, the verification procedure has been reversed to develop a volumetric verification concept installed on the machine tool to overcome the constraints of the procedure currently in use and deliver a fully automatic solution that has only one measuring system.

IK4-TEKNIKER presented this solution at 22nd edition of the Conference on Advanced Manufacturing and Machine Tools that took place at the Gipuzkoa Science and Technology Park on October 23-25 2019 by giving a presentation entitled “Integrating and automating volumetric compensation and verification. A process for machine tools”.