PROJECTS

IK4-TEKNIKER research work addressing Laser Metal Deposition, Wire LMD has progressed even further as the organisation has plans to manufacture its own machine. This development will be presented at the upcoming edition of the Basque Industry 4.0 conference.

Additive manufacturing has brought a revolution with regard to how parts and components are manufactured as the material deposition technique, mainly metal-based, allows complex shapes and structures to be made which is something that traditional processes cannot do.

This new technique offers a number of possibilities. Namely, the manufacture of new geometries, maximum material utilisation as well as reinforcements and/or repairs for high-added value parts so they do not have to be manufactured again. A significant advantage.

More specifically, manufacturing processes using Laser Metal Deposition, Wire LMD are based on technologies that optimum future prospects as regards manufacturing large-scale structures made up of iron, nickel and aluminium-based alloys for leading sectors such as the aeronautical business.

Compared to other conventional direct material deposition techniques in manufacturing, as heat is applied in a very focused manner it means that minimal deformation occurs on the base where the material is deposited and on the structure where it is generated.

Compared to the Laser Metal Deposition, Powder LMD technique, Wire LMD is extremely efficient as nearly 100% of the material deposited will eventually form part of the structure that is generated. The technique also delivers high productivity ratios and can climb beyond 4 kg/h to achieve enhanced mechanical properties.

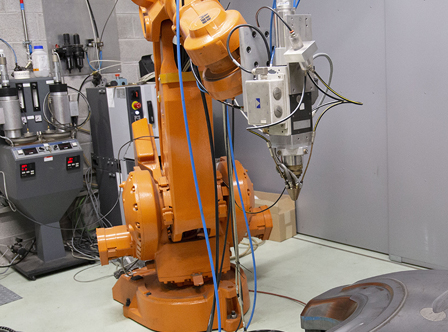

IK4-TEKNIKER, in addition to developing the Wire LMD process, has also designed and built an additive manufacturing machine based on the Wire LMD technique. This equipment has enough capacity to manufacture structures measuring up to 1900 x 900 x 750 mm at productivity rates in excess of 2 Kg/h and with different materials, especially titanium alloys, as vacuum and controlled atmosphere operations under five parts per million of oxygen are possible.

This development will be presented under the title “Additive Manufacturing of structures using the Wire LMD technique” at the upcoming edition of the Basque Industry 4.0 conference to be held at the Bilbao Exhibition Centre (BEC) in Barakaldo on November 20-21.