PROJECTS

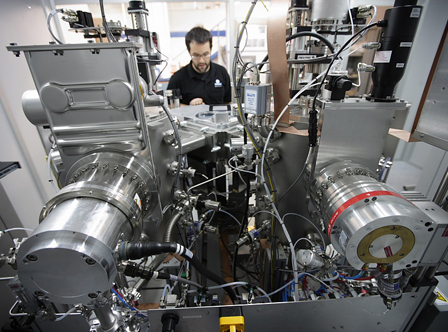

IK4-TEKNIKER has innovated to take a step forward in the industrial implementation of new PVD (Physical Vapour Deposition) technologies, used in the coatings industry for mechanical applications like automotive components, gears or cutting tools, thanks to the development of the HIPIMS (High Power Impulse Magnetron Sputtering) project.

PVD is a type of technology involving thin film coatings (from tens of nanometres to microns) that are obtained by vacuum evaporation. Through this technique, it is possible to obtain extremely tough coatings that increase component life. Furthermore, it allows the surface properties of a material to be modified in order to obtain the desired features, like improvement in resistance to corrosion or abrasion.

The HIPIMS project consists of the implementation of a new evaporation technology that can achieve a greater ionization of the evaporated metal and a coating with enhanced properties. This improvement is achieved by means of high power pulses during a short period of time, a process that achieves greater ionisation of the material than the current sputtering techniques, so it offers better properties for protecting against wear or corrosion.

IK4-TEKNIKER, which has been working on the HIPIMS project for the last two years thanks to the Emaitek programme of the Government of the Basque Autonomous Community (region), has developed this technique for the first time in Spain.

One advantage of this technique is that this technology can be implemented without major modifications having to be made to the current PVD machines. The main difference lies in the power source of the evaporators.

The early results obtained with tantalum nitride coatings are highly encouraging. After optimizing the process conditions for this technology and this specific material, IK4-TEKNIKER has obtained totally isotropic, dense layers that cannot be achieved through the conventional sputtering technique. What is more, the corrosion tests carried out on the samples of tantalum nitride evaporated by means of HIPIMS have displayed better behaviour than the ones deposited by means of conventional technology.