PROJECTS

There are nowadays several types of solar thermal electric power plants that are doing their utmost to become leaders in the solar power market. In this effort to keep ahead of the competition, companies are primarily focusing on minimising costs connected to all the devices and systems used to better harness the energy provided by the sun.

As regards the current range of alternatives in terms of solar thermal electric power technologies such as, for instance, cylindrical parabolic collectors (CCP) or Fresnel collectors, most experts believe that tower solar power stations offer greater expectations as regards eventually becoming the most efficient system of them all.

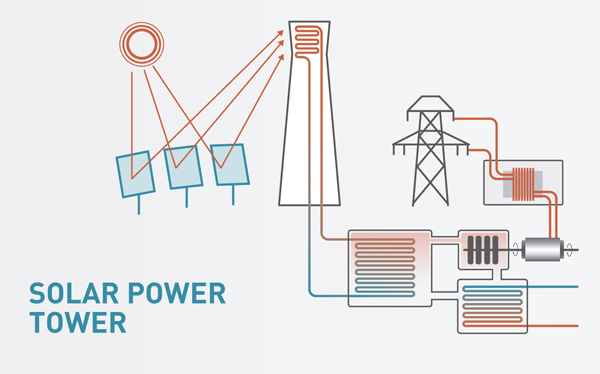

These thermal electric plants are equipped with a central tower that receives sunlight from reflections produced by a number of solar collectors that surround it. These collectors, or heliostats, are fitted with moving mirrors that constantly reflect sunlight on a receptor installed at the top of the tower.

There are, nowadays, several reasons to support the fact that this system will actually play a far more outstanding role in the market in the near future:

- As this technology can attain higher concentration ratios, it means that higher temperatures and efficiencies can be achieved.

- The thermal circuit and receptor are not scattered throughout the solar field, but contained inside the tower which allows for a significant reduction in the size of this critical part. Consequently, not only are costs reduced, but thermal losses and operating risks associated with freezing the fluid that carries heat are also diminished.

- In most instances, the fluid used in these towers both as a storage medium and a carrying system is made up of molten salts. This avoids having to use an additional exchanger, as occurs in other configurations and, consequently, makes it possible to reduce thermal losses, provides a more straightforward plant layout and diminishes costs.

- As higher temperatures are reached in tower systems, the storage device is more competitive because the cost per unit of stored power is lower. It has, in fact, proved to be a competitive option for power generation during extensive periods when there is hardly any sunshine.

Although compared to cylindrical parabolic collectors there are very few tower plants in operation, the cost of both technologies has been analogous in recent bids. Experts believe that, in order to achieve greater cost reductions, the focus should shift towards heliostats located in the solar field, although two apparently contradictory lines of development have been observed.

On the one hand, very large heliostats are being developed, particularly at a European level. Solar thermal electric power plants have less of these devices in the field. Systems of this kind are fitted with very expensive high accuracy drives that require bigger reflecting surfaces to reduce installation costs per m2.

On the other, a number of companies, mainly North American, are developing small heliostats to simplify structures, eliminate operations such as edging, and facilitate installation work by using mass-produced components. There will, in fact, be a significant increase in the number of heliostats required which will make possible to implement serial manufacturing.

It is within this context that the CENER (National Centre for Renewables) Technology Centre and IK4-TEKNIKER have joined forces to develop an innovative heliostat concept also known as EASY (hEliostas for eAsy and Smart deploYment). It is a small device that intends to reduce solar field expenses by up to 100 $/m2.

The development includes a novel tracking system driven by low-cost motors. This system features a reduction system based on cables that deliver a smooth operation at an extremely low cost. The end result is a very high level of accuracy in the positioning of heliostats at a lower cost.

Contrary to what happens to bigger heliostats, structural deformations produced by wind are minimised and mirror edging will tend to disappear.

The first developments have already been tested at the facilities of the Solar Platform in Almería and it has been verified that the system does meet all the necessary requirements. Although low-cost components are involved, the system is more accurate than those used until now.