PROJECTS

In the interests of quality and cost management, this new laser beam characterization and diagnostic service allows the characteristic beam parameters of the lasers to be measured on the actual premises of the company.

Spanish industrial companies and those belonging to the Basque Country’s business base, in particular, are incorporating more and more power lasers into their production processes, not only for cutting and welding applications but also for surface treatments (texturizing, hardening, etc.).

So those who run companies using laser technology have started to pay increasing attention to the state of their equipment. The companies that use laser technology are increasingly aware of the key importance of a good service to diagnose possible faults or for certifying the quality of the laser beam in order to maintain quality and manage costs.

Aware of the value of companies being able to show their clients that their laser systems are operating in optimum conditions, IK4-TEKNIKER has launched a new service for characterizing and diagnosing laser beams; in situ right on the company's premises it allows measurements to be made of the beam parameters that feature in the most common lasers on the market (diode, Nd:YAG, CO2, fibre, disc, etc.).

The R+D centre is thus putting into the hands of its clients a tool that will enable them to diagnose possible faults in the beam’s optical path (dirt, damage to the optics, problems of misalignment, etc.) as well as the functioning of the laser itself. It is a service geared towards companies that use high power lasers mainly for cutting, welding and thermal treatment applications.

Spotting defects

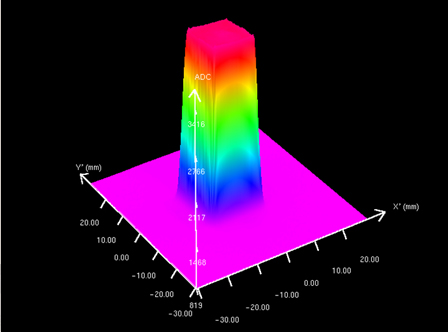

The new service is capable of determining the most important characteristics of laser systems (optimum working distance, minimum beam diameter, intensity profile, divergence, etc.). It can also spot defects in the optical guidance system of the beam, which can affect the process. The aim is to provide companies with a system that will ensure the quality of their laser processes and cut costs, thanks to the optimized maintenance of their equipment.

Nevertheless, IK4-TEKNIKER's characterization service also makes it possible to know the actual power that is reaching the part, as opposed to what is stated on paper. This enables companies to know how the laser is performing, and what power losses may be caused by the optical system.