NEWS

Within the framework of this agreement the company METRONIC is also joining in order to distribute the laser tracer.

In its strategy to offer companies new high added-value solutions and services, IK4-TEKNIKER has reached agreement with the German company ETALON AG, the developer of the laser tracer and all the measuring/volumetric compensation software associated with this equipment, to be its equipment distributor through the company METRONIC. It will also be offering a new volumetric verification/compensation service based on this solution.

This new service will complete the broad range of services offered by IK4-TEKNIKER’s Metrology Unit. It will thus enable both manufacturers and users of machine tools (MT) and coordinate measuring machines (CMM) to get to know and improve (through compensation) the volumetric precision of their machines.

Right now, machine tool builders and users are seeking to assess the positioning precision of the machines as accurately and rapidly as possible to minimize, firstly, downtimes, and secondly, environmental effects, which are mainly thermal ones.

The suite of classical tools used to commission the machines, like levels, set squares and linear interferometers are not adequate for measuring larger machines when the characterisation of the whole work volume is being sought.

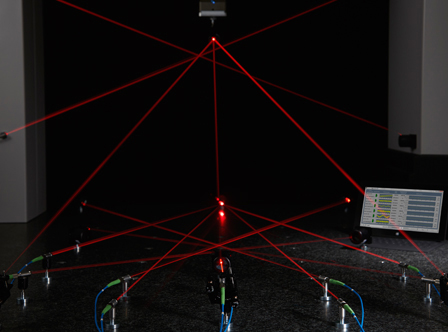

The most innovative technology for measuring the geometric errors of a machine is interferometric multilateration. The latter is a well-known mathematical technique because it is used in GPS navigation. It involves taking measurements of the linear distance to the body to be measured from different measuring stations. After that, the equation systems are solved using mathematical methods, and the result obtained is the position in the reflector space, and with it an error value in each position in the work space.

The equipment that can be used to apply this technique are laser trackers (using the interferometer alone) or laser tracers. The main difference between the laser tracer and the laser tracker is that the former lacks encoders for measuring angles because this equipment has been designed only to measure by means of the multilateration technique.

The geometric verification of a large machine tool throughout its volume of work is for IK4-TEKNIKER one of its priority fields in its line of expertise in metrology.

IK4-TEKNIKER has developed an in-house solution for volumetric verification by means of multilateration techniques by using a laser tracker combined with the use of electronic levels. The knowledge acquired has enabled customised solutions to be developed for machine tool manufacturers and users and continues to be a priority line of work to tackle aspects like the self-calibration of machines, alignment of parts and structures, and even in-situ measuring as a future aim.

All this work has been made possible by the Emaitek and Etorgai programmes of the Government of the Basque Country (Hiperion project), and by the CDTI-Centre for the Development of Industrial Technology (Impeler project), and also by close collaboration among Machine Tool manufacturers, the main ones being Zayer, Juaristi, Goratu and Ona.