NEWS

IK4-TEKNIKER is currently collaborating with ULMA to integrate technology and allow a transport system to operate as if it were a cyber-physical system.

Based on its strategic approach, ULMA Carretillas has promoted new business models as an integrated supplier of logistic services.

Their aim is to offer customised, comprehensive logistic solutions allowing customers to achieve high levels of performance via efficient and professional management actions geared towards attaining higher levels of safety, greater cost reductions and longer life cycles for the means used by applying predictive techniques, repairing and refurbishing forklift truck components to facilitate reuse and adapting solutions to how they are actually used.

Amongst a host of other things, they offer several renting and pay-per-use modalities for their forklift trucks. They also have a comprehensive fleet management service that offers customers a fully guaranteed system addressing correct maintenance actions for the equipment used at their facilities, gradual replacement of vehicles with new models and a continuous adaptation of the type and number of forklift trucks to specific work requirements.

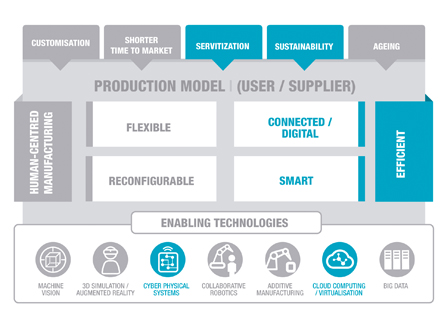

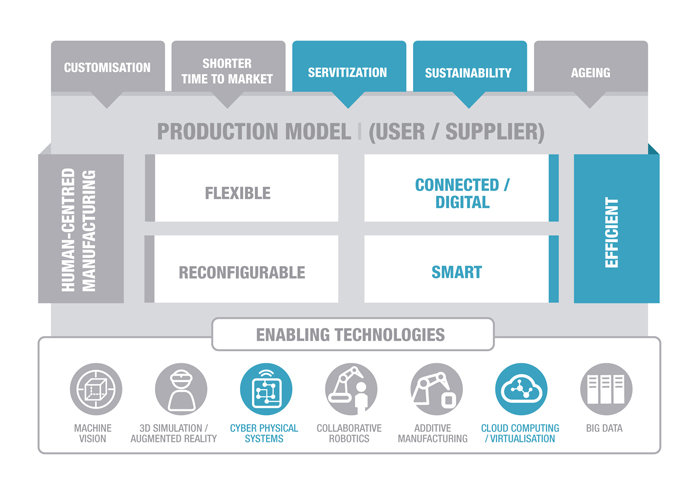

The strategy followed by ULMA in terms of the Industry 4.0 production model is fully in line with the concept of smart and connected means of production and the opportunities arising from a close co-operation between the user and the supplier of said means.

Therefore, the main features of ULMA’s production model are focused on the efficiency of their own processes and those of their customers; the incorporation of “intelligence” in production means and the connection/digitization of the processes and means used.

IK4-TEKNIKER is currently collaborating with ULMA to integrate technology and allow a transport system to operate as if it were a cyber-physical system.

Specifically, forklift trucks are to be fitted with hardware/software to undergo continuous monitoring with regard to their use and condition; predictive know-how will also be used for the timely detection of symptoms of potential future problems involving critical elements such as batteries, for instance.

Likewise, forklift trucks will feed data into a remote server so that, based on this information, it will be possible to optimise maintenance strategies, carry out timely repairs or refurbishment work and pinpoint new transport needs.

This project has received funding from the European Community's Seventh Framework Programme (FP7-FoF-NMP-2013-8) under grant agreement no 609005.