NEWS

IK4-TEKNIKER is collaborating with Ibermática to incorporate the so-called enabling technologies of Industry 4.0 to its product range. These are related to “plug&produce” components, cyber-physical systems, analytical capabilities and decision making support actions.

There are nowadays many companies dealing with scenarios where flexibility and reconfigurability are required; solutions linked to production management and control must flow in the same direction. One of the contributions made by Ibermática allows for the easy reconfiguration of solutions.

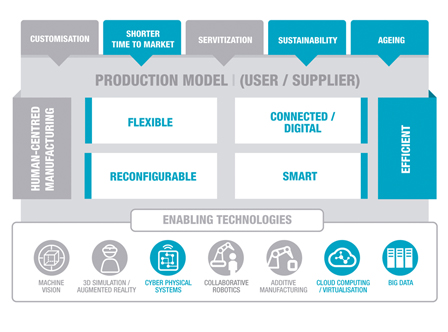

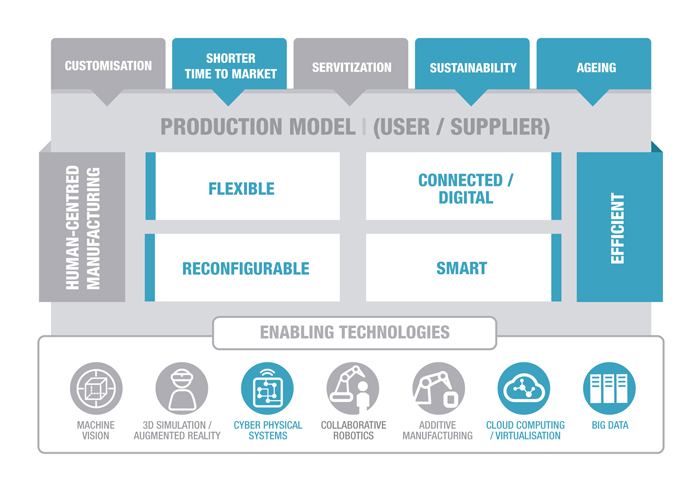

Ibermática Industria intends to offer a comprehensive range of solutions for the industry, ranging from engineering to production processes and generic management actions. When dealing with Industry 4.0 challenges, their remit is to assist companies in the implementation of a production model that is fully in line with the value proposition of a business.

It was from 2010 to 2013 and even before the term Industry 4.0 was coined when Ibermática and IK4-TEKNIKER jointly led a European initiative called COSMOS, “Cost-driven Adaptive Factory based on Modular Self-Contained Factory Units” focused on designing, managing and monitoring flexible and evolutionary production lines.

The aim of COSMOS was to introduce flexible, modular and evolutionary concepts to monitor product assembly plants and lines and integrate engineering and production, “plug&produce” components and HMI for the ultimate purpose of supporting and verifying assemblage activities.

On the other hand, and in line with the possibilities offered by sensors and so-called cyber-physical systems, Ibermática has incorporated these technologies to their products by shifting its “production control” focus and moving towards “process control” to monitor the most significant variables.

In this regard, Ibermática is currently undertaking implementations with end customers; PIERBURG, COPRECI and MICRODECO are some of the companies currently incorporating innovative technological approaches connected to the Industry 4.0 concept.

Moreover, and pursuant to efforts made to enable their products to enter new areas characterised by connections to sensors, cyber-physical systems and analytical and supportive decision making capabilities, Ibermática is co-operating with IK4-TEKNIKER to carry out several new R&D initiatives.

Special emphasis must be made of the background provided by IK4-TEKNIKER as a result of its involvement in FoFdation, ‘The foundation for the smart factory of the future’.

The main goal of the project was to lay the foundations for the “Factory of the Future” by applying end-to-end digitization of the product, the process and the resources of the machine itself. Advanced information of this kind has made it possible to develop three horizontal applications consisting in monitoring processes and their degree of energy efficiency, optimising processes and production controls using an extended MES system (Manufacturing Execution System) characterised by sustainability and energy efficiency goals to make better use of resources during production; this activity was carried out by IK4-TEKNIKER.