PROJECTS

It is essential to correctly validate the measuring principle so that theoretical formulations developed in a research process may materialise and eventually become sensors with a high technological value.

Research centres and universities carry out theoretical formulations that later appear in publications or patents. Work can either finish at this point in time or continue by searching for a real application that will transform an idea into a market product.

The path between theory and practice is covered in close cooperation with companies and starts by validating the measuring principle, a process that consists in identifying the scientific base of a measurement and discovering any factors that might influence the outcomes of a future experiment.

Temperature, humidity and vibrations are amongst the most frequently studied factors in the industrial environment.

It is important, in this context, to take into consideration the real working environment in which the measuring principle is to be applied in order to determine maximum and minimum values to be allocated to the factors studied and to correctly define the conditions under which trials are going to be run.

Once these features have been identified, they must be replicated in the laboratory and checks must be performed to ascertain whether the factor studied has a significant effect on the measuring principle.

Sometimes, the conditions under which trials are performed are defined by international standards, such as those set forth by ASTM. On other occasions, however, these standards do not apply and the researcher must establish the conditions according to which an experiment is to be carried out.

Validating sensoring systems based on Infrared spectroscopy (IR)

Consisting in performing real-time monitoring of a specific type of analyte (a relevant analytical component of a sample) related to production and quality parameters with regard to solid and liquid substances.

This measuring principle usually applies to industrial lubricants (oils and HTF fluids) and food (milk, cider, wine, kiwis and tomatoes), amongst others.

Validating electrochemical measuring technologies

Electrochemical detection techniques for biomarkers stand out in terms of sensitivity, simplicity, low cost and portability. Moreover, only small sample quantities are required.

As regards electrochemical detection techniques, IK4-TEKNIKER uses amperometry. This technique continuously monitors current resulting either from and oxidation reaction or from the reduction of an electroacitve species under a constant potential. On most occasions, the latter will be the redox reaction catalysing the HRP enzyme. This enzyme is used as a marker for the antigen-antibody reaction, which is what actually confers specificity to a detection process.

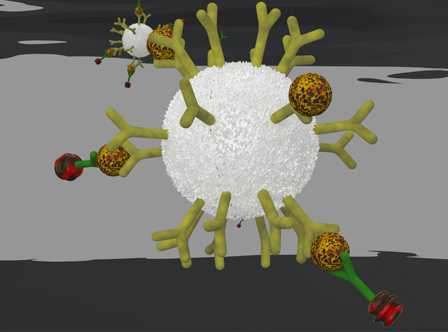

Validating biosensors based on optical phenomena

In theory, and due to the properties found in a metal such as gold, whenever light impinges on a thin layer of this material, a plasmonic excitation effect is produced emitting a light on the surface of the metal whose spectrum is characteristic of the light source with which it has been illuminated, of the metal and of the medium in contact with the above mentioned layer of metal. This is how said spectrum for a light source, a metal and a given medium is known. If the medium is changed, a change of spectrum will follow.

IK4-TEKNIKER has addressed the possibility of applying this physical principle to develop a biological sensor.