NEWS

IK4-TEKNIKER is participating in the European HipIndMould Project, which is seeking to bring about the industrial use of the latest technological advances in the coating of plastic injection moulds.

The increasing demand for the use of polymers with a high fibreglass content means that the plastic injection moulds are being blighted by severe wear and corrosion problems. Downtimes and maintenance tasks account for 10% of the total production cost. Yet to produce aesthetic components, the surface finish of the mould is critical and any fault in it can lead to the rejection of up to 75% of the injected components.

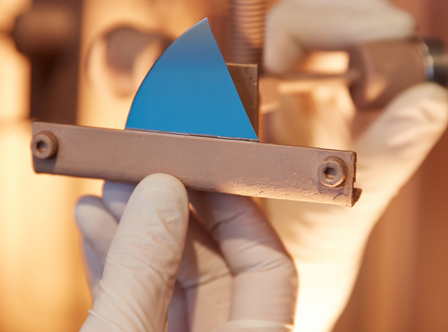

PVD (Physical Vapour Deposition) coatings are used in this field, and thanks to a thickness of just a few microns in the layer they improve the performance of the mould; this is also an environmentally clean alternative to electrolytic processes. However, within this technology there is a new, promising variant known as HiPIMS (High Power Impulse Magnetron Sputtering), which offers excellent advantages in terms of hardness, density and surface finish of the coating. It is reckoned that using it in plastic injection moulds could increase their useful service life by 20% and that its use will make it possible to increase the productivity of the processes by 10%. Right now, this new technology is facing a number of challenges before it can take the definitive leap from the laboratory to industrial production.

The European HipIndMould (Optimized Industrial HiPIMS system for coating Plastic Injection Moulds) project, in which IK4-TEKNIKER is participating alongside the company FLUBETECH, is seeking to bring about the industrial application of HiPIMS technology in plastic injection moulds used to manufacture components for such wide-ranging sectors like the automotive, medical and packaging sectors.

The IK4-TEKNIKER researcher Cristina Zubizarreta is in no doubt that HiPIMS technology is leading to high added-value coatings in the laboratory but some aspects still need to be polished to achieve a robust industrial process that can guarantee production reproducibility and repeatability.

In the project IK4-TEKNIKER will be bringing its cutting-edge knowledge in HiPIMS technology on an equipment as well as process development level so that an industrial plant for mould coatings can be set up.

The HipIndMould project, the first phase of which commenced last October and which has funding to the tune of 50,000 euros, involves drawing up the feasibility and business plan. Once the first stage has been completed, the project could be ready for a second phase that would take two years and in which the contribution of European funding will be between 1 and 3 million euros.