PROJECTS

IK4-TEKNIKER is working on the European project HITECO, funded by a 5-million euro budget and geared towards improving the efficiency of an innovative technology for concentrated solar power and cutting the costs involved.

Nobody is casting doubt any more on the huge future potential of solar power, but the current technology is facing difficulties like efficiency, which remains limited when it comes to transforming sunlight into electricity. That is why, rather than focussing on the more extended formula of photovoltaic panels, researchers are already working on other technologies that will allow the juice to be "squeezed" out of solar energy better.

One of these new technologies is solar concentration which involves focussing reflected sunlight onto a series of mirrors in a very small area until a very high temperature is reached. The energy is stored in the form of heat to be later transformed into electricity. This storage capacity is what turns it into one of the renewable energy technologies that is gaining more appeal for the power market. However, the mass dissemination of this technology still depends on cutting costs and increasing efficiency.

In order to increase the generating capacity of this technology, the European Commission through its 7th Framework Programme has launched the HITECO project; it has a budget in excess of 5 million euros, and the Basque R&D centre IK4-TEKNIKER is collaborating in it, along with another 9 R&D centres and companies in Spain, Switzerland, Germany and the Czech Republic.

The project, led by the company Aries Ingeniería y Sistemas, also has the collaboration of the Industry Association of Navarre, the Cidaut Foundation, the Institute of Materials Science in Madrid, the Swiss centre ETH, the Czech company Kavalierglass and the German companies Witzenmann, Trelleborg and Pfeiffer.

Concentrated light

Solar concentration technology functions differently from the classical solar energy of photovoltaic panels. In plants of this type the sun is reflected onto huge mirrors that reflect the radiation onto a central tube. The fluid circulating inside the tube is heated to several hundred degrees centigrade and is pumped to a plant where the heat is transformed into electrical power by means of turbines.

This technology is still a long way from reaching maturity and to date there are only two top companies in the world with the capacity to set up plants of this type. The HITECO project, which is highly complex, is seeking to improve efficiency in each of the elements in a solar concentration plant, from the coating of the tubes, to thermal insulation and including vacuum control and joints. There are 10 work packages in all with IK4-TEKNIKER involved in a third of all the research areas.

Interdepartmental co-operation

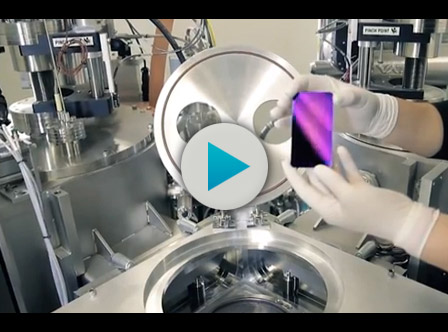

Given the sheer size of the project, a number of departments in the R&D centre (for example, mechatronics and electronics) are involved in the various work packages alongside experts in PVD (Physical Vapour Deposition), a technique for applying materials to provide the surfaces of materials with specific properties.

One of the main aims of the project is to increase the temperature of the heat transfer fluid, currently at 400 degrees centigrade. By means of various innovations, including a coating that allows that greatest possible amount of solar radiation to be absorbed and which minimizes heat losses, the HITECO project is seeking to reach a temperature of 600 degrees.

For this purpose, IK4-TEKNIKER has designed a coating with different layers of superimposed metal oxides, a highly reflective metal and an absorbent cermet, which allows the nearby infrared solar spectrum as well as the visible one to be captured.

What is more, the centre has also built a machine to be able to deposit selective coatings onto 4-metre long tubes, a key innovation in the standardization of the technology developed and its scaling for reliable mass production.

The system has a 12-metre long vacuum chamber and 4 evaporators. The control of the thickness of the layers is crucial in these coatings. The system developed by IK4-TEKNIKER can achieve homogeneity of 5 nanometres all over the tube perimeter and throughout the 4 metres of its length.

In order to put the innovations developed in the HITECO project into practice, the consortium members are building a pilot plant for which IK4-TEKNIKER will be providing 100 metres of tubes equipped with the advanced surface coating.

The results of the project will help to lower the manufacturing costs and maintenance of solar plants of this type. The efficiency of the energy transformation process is also expected to be increased by raising the working temperature of the collectors. All this means that it will be possible to multiply the number of solar plants and that the consumption of this source of renewable energy will become widespread.

This project has received funding from the European Community's Seventh Framework Programme (FP7-ENERGY-2010-1) under grant agreement n° 256830.