PROJECTS

The European INTEFIX project, led by IK4-TEKNIKER and with funding of 7.5 million euros from the European Union’s 7th Framework Programme, sets out to improve the productivity of machining processes in European industry and to reinforce high added-value industry.

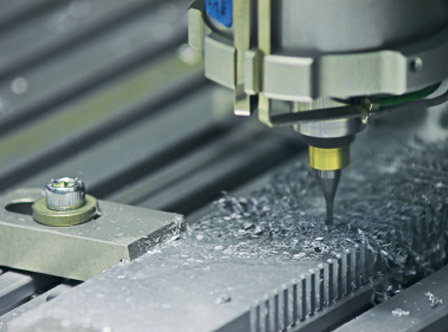

High added-value products made of high performance materials, like those used in the aeronautical, space or energy sectors, require the highest precision and quality during the machining process. Nevertheless, the effectiveness of conventional process engineering is limited when it comes to improving the manufacture of products of this type.

That is why the European Commission has committed itself to the INTEFIX project, which has funding amounting to 7.5 million euros. It aims to increase the performance of machining processes through the use of intelligent tooling systems; these systems enable the processes to be supervised, monitored and adapted in order to obtain results that are more precise, cheaper and of higher quality.

The project led by IK4-TEKNIKER starts from one point in the evolution of machining in which the traditional requirements are no longer sufficient. Right now, the demands of the business base include higher levels of precision and performance and this requires that the tooling should take into account aspects like deformations, vibrations or distortions that occur during production.

The mission of INTEFIX is an ambitious one, since it is designed to have an impact on global markets and reinforce the market position of the high added-value manufacturing industry. This is an economic sector with a significant weight in advanced economies, since the metal industry accounts for about 10% of the European Union’s industrial added value and employs 12.5% of its workers.

Intelligent technology

INTEFIX will be incorporating cutting-edge technologies, like sensors, actuators, control algorithms and simulation tools, with new tools developed expressly for the purpose of obtaining intelligent tooling accessories. These devices are capable of modifying the behaviour of the tooling itself and the process/tooling/machine interactions in the machining operations, so they are able to cut operation time and costs.

What IK4-TEKNIKER is contributing to the project has to do with the development of solutions to prevent vibrations and deformations in the lathe work of large workpieces; this involves incorporating intelligent elements into the right areas of the tooling equipment to control the behaviour of the workpieces and achieve a better result in the process. The R&D centre will also be leading the creation of a raft of cutting-edge technologies that will enable the problems in the positioning of the workpiece being manufactured to be solved.

The initiative includes work to determine the specifications of the project, the design of the working methodology and process mapping to characterise technological solutions. IK4-TEKNIKER will also be undertaking the design of case studies of two of the 15 work packages that comprise the INTEFIX project.

The results of the project will constitute another step towards intelligent manufacturing by providing new functionalities in the manufacturing systems and equipment based on automation, flexibility, versatility, efficiency and precision.

At the same time, the results will be contributing towards improving Europe’s competitiveness in the industry of high added-value product manufacture, and in the development of technological advances in the field of intelligent systems. It will also constitute scientific and technological advances that will enable universities and research centres to remain at the forefront of research and development.

This project has received funding from the European Community's Seventh Framework Programme (FP7-2013- NMP-ICT-FoF) under grant agreement n° 609306.